Biogas production

As global demand for biogas and biomethane production increases, these renewable fuels are becoming vital in reducing greenhouse gas emissions and supporting a circular economy. The biogas process converts organic feedstock and waste into valuable energy sources through a series of controlled stages, including pre-treatment, digestion, and post-treatment. Efficient separation and heat transfer technology from Alfa Laval ensures that every step maximizes yield, energy recovery, and sustainability

Accelerating growth of biogas production

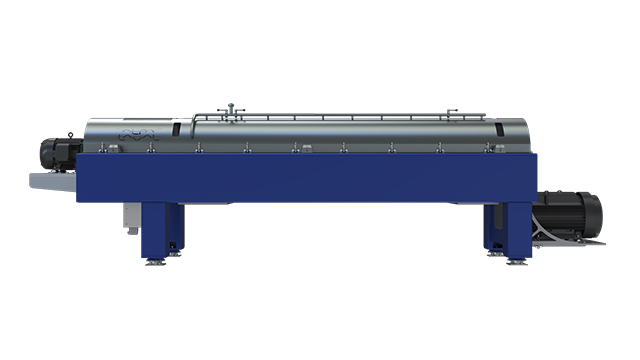

- Higher solids recovery, maximizing resource utilization with Aldec decanter centrifuges and drum thickeners

- Quick and efficient installation with Alfa Laval global support

- Skid is available for the oil separation process in anaerobic digestion

- Superior heat-transfer and maximum operating efficiency with gasketed plate and spiral heat exchangers

- Access to Alfa Laval process knowhow and global network of service

The biogas production process begins when organic waste, such as organic feedstock, food waste, manure, or sludge, is broken down in oxygen-free tanks. Microorganisms convert this material into biogas, a mixture of methane and carbon dioxide, and digestate, which can be used as fertilizer.

Each phase of the biogas process must be carefully controlled to achieve efficient gas yield and reduce emissions, ensuring a sustainable and scalable biogas generation system. With decades of experience supporting biogas plants worldwide, Alfa Laval delivers proven solutions for a wide range of feedstocks, including paddy, Napier grass, organic waste, and municipal solid waste.

Our technologies ensure optimal biogas production, maximum energy efficiency, and even enable water reuse, helping operators achieve sustainable and cost-effective performance.

Key products

Meet our experts

A vital part of the patented oil extraction process is the Prodec Oil Plus, which integrates easily into any anaerobic digestion facility. It efficiently extracts oils, fats, and grease from organic waste before methanogenesis, allowing the cleaned material to return to the anaerobic digestion system with minimal biogas loss. The result is bio-crude with up to 99.5% purity, ready for refining into sustainable aviation fuel.

Happy customers

Partner with experts in biogas production

Alfa Laval experts can help biogas operators improve resource efficiency and reduce, reuse, and recycle waste so that you optimize your production processes and achieve more sustainable results. Whether it’s the establishment of new biogas plants or the expansion of existing ones, our expertise in heat transfer and separation technologies, along with a global service and support network, enables quick and efficient set up.

Partnering with Alfa Laval also means you get access to our global presence and network as we take care of the lifecycle of your critical heat transfer and separation equipment.

"Alfa Laval’s spiral heat exchangers are vital equipment for stable operation of our digester and overall plant economy as it saves a lot of money through heat recovery," - Lars Albak Kristensen, Plant Manager, Lemvig Biogas Plant

AGSM (Azienda Generale dei Servizi Municipalizzati) in Verona, Italy, uses an ALDRUM MegaDuo to thicken solid waste from 5% to 13% DS without using polymers. The sludge is then transferred to an anaerobic digester to produce biogas.

Pre-treatment in the biogas production process

When treating municipal solid waste in a wet system before anaerobic digestion, several steps take place, including milling, magnetic separation, pulping, inert separation, thickening, and hygienization. Thickening the pulp using Alfa Laval drum thickeners and decanter centrifuges offers benefits such as reducing the load on downstream processes, lowering energy consumption, and increasing biogas yield. The water from the pulp can also be recycled. Regulations often require hygienization and can be achieved through pasteurization using efficient spiral heat exchangers, which help maintain stable anaerobic digestion by controlling the sludge temperature closely.

Anaerobic digestion in biogas generation

Anaerobic digestion is a crucial stage in which microorganisms break down the pulp without oxygen, producing methane and carbon dioxide gas. Prior stages aim to optimize the digestion process by increasing dry solids feed, controlling temperature, and enhancing capacity and biogas yield. Post-digestion stages such as dewatering and nutrient recovery are vital for closing the loop, supporting biogas processing and sustainable energy generation, which Alfa Laval achieves through high-performance decanter centrifuges. Spiral heat exchangers can also be used for post-digestion hygienization, offering benefits similar to those in the pre-treatment stages.

Oil separation in anaerobic digestion for diversified biofuel production

Oil separation in anaerobic digestion for a diversified revenue stream

Alfa Laval is working with AD operators globally, placing the Prodec Oil Plus decanter centrifuge between the acidogenesis and acetogenesis stages of anaerobic digestion, creating ideal conditions for oil separation. The innovative decanter centrifuge near the pasteurizer allows for slurry separation without impacting the overall process. The unique operation of the decanter prevents solids from compacting within the chamber, ensuring that all oil introduced into the machine can be fully recovered.