Nuclear power

Alfa Laval delivers a wide range of highly reliable and efficient cooling solutions, certified up to safety class 2, as well as systems for treatment of oils and wastewater. Whether you are developing a new large-scale reactor (LSR), a small modular reactor (SMR), or upgrading an existing plant, our experts can help tailor the optimal solution, ensuring outstanding long-term performance.

How does Alfa Laval help the nuclear industry meet its challenges?

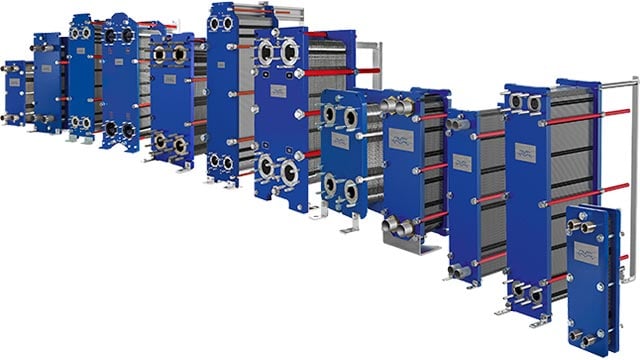

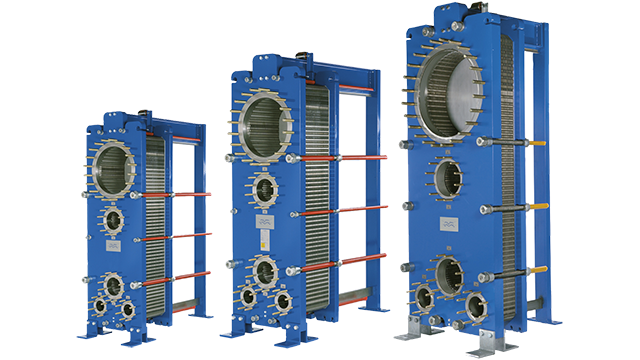

- Our compact, flexible heat exchangers are ideal for both new-builds and upgrade projects – for LSRs as well as SMRs.

- Increase capacity when conditions change by simply adding plates, for example when cooling water temperatures or thermal loads rise.

- We comply with nuclear regulations in most countries worldwide.

- Our global footprint and resilient supply chain ensure reliable, on-time deliveries.

- Thanks to their compact design, our solutions generate minimal waste at decommissioning.

Which are the typical applications for Alfa Laval equipment in water-cooled large-scale reactors (LSRs)?

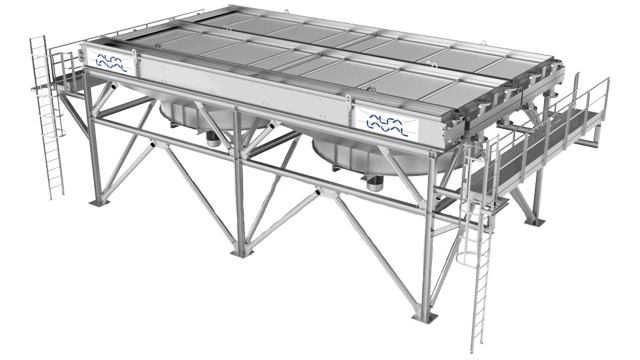

We offer solutions for the nuclear island, the turbine island, and balance of plant systems. Applications include, among others, central cooling, spent fuel pool cooling, and emergency cooling, as well as cooling-water treatment, wastewater treatment, and oil cleaning and cooling.

- EDG Intermidiate closed loop water cooling

- Lube oil cooling and cleaning

- Fuel oil treatment

- Residual heat and emergency reactor core cooling

- Spent fuel pond cooling

- Close loop cooling and filtering for nuclear island systems (or for safety related systems)

- Lube oil cooling

- Feed water pumps lube oil cooling and cleaning

- Close loop cooling and filtering for turbine island systems (or for non-safety related systems)

- Cooling and condensing for the make-up water systems of both nuclear and turbine island

- Turbine lube oil cooling & cleaning

- Generator cooling

- Insulating oil cooling & cleaning

- Waste water treatment

Why are plate heat exchangers superior to shell-and-tubes in many nuclear applications?

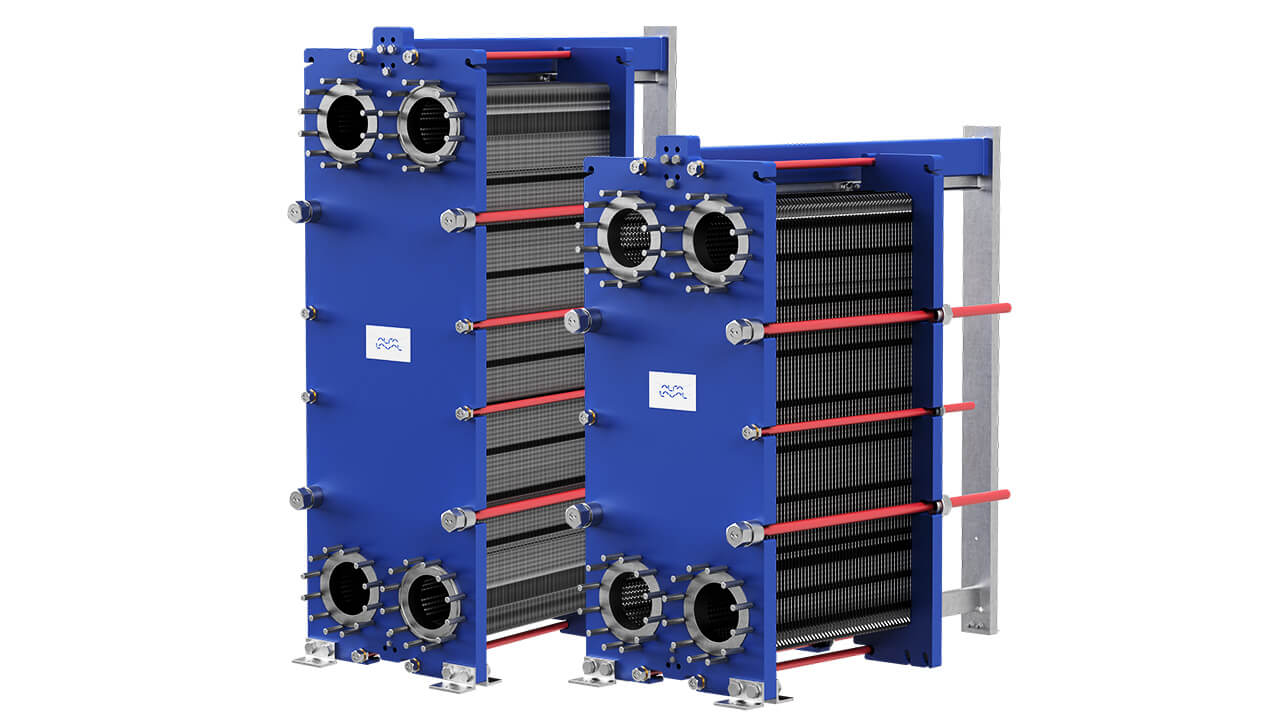

There are numerous positions in a nuclear power plant where plate heat exchangers are a superior alternative to traditional shell-and-tube designs. Gasketed and semi-welded plate heat exchangers are well-proven, highly reliable technologies that offer:

- High thermal efficiency and a compact footprint, making them ideal replacements when capacity must be increased and space is limited.

- Opportunities for system-level optimization when designing new cooling systems, helping reduce both CAPEX and OPEX.

- Built-in flexibility, as performance can be increased by simply adding plates – a major advantage when operating conditions change.

- Minimal maintenance needs, the only routine task is gasket replacement every 10–15 years.

- Easy servicing, with full access to heat transfer surfaces and very little space needed around the unit.

Products

Customer stories from in the nuclear power industry

Energizing France

Alfa Laval has been a key supplier to Electricité de France’s nuclear power stations for decades, delivering many plate heat exchangers along with on-site maintenance and reconditioning services.

Reliability at the core

British Energy installed eight Alfa Laval ALF seawater filters at the Heysham II nuclear power plant to ensure maximum availability of clean cooling water.

How is Alfa Laval supporting the development of small modular reactors (SMRs)?

SMRs are driving a new wave of innovation in nuclear power, and Alfa Laval’s high-efficiency heat exchangers are perfectly suited for this new generation of reactors:

- Compact size – easy to modularize and fit into small spaces.

- Short lead times thanks to serial production, enabling rapid scaling and replication across multiple sites.

- Design support worldwide to help you maximize system performance when integrating our technology.

- Global support and maintenance throughout the equipment’s entire lifecycle.

- Low maintenance requirements and long lifetime.

Which standards do Alfa Laval’s products comply with?

Thanks to our industry-leading quality management system, many of our products meet virtually all relevant national and international standards. As a result, they are pre-qualified for installation in nuclear power plants worldwide.

We comply with a wide range of design codes, including:

- ISO 19443

- ISO 9001

- ASME sec. III, N stamp

- ASME sec VIII, U stamp

- RCC-M

- PED

- EN 13445

- Canadian Standard Association

- KTA 1401

- HAF

- PNAE G

- YLV

What service and maintenance support does Alfa Laval offer?

Reliable uptime is essential for nuclear power plants, making service and maintenance a key consideration when selecting equipment

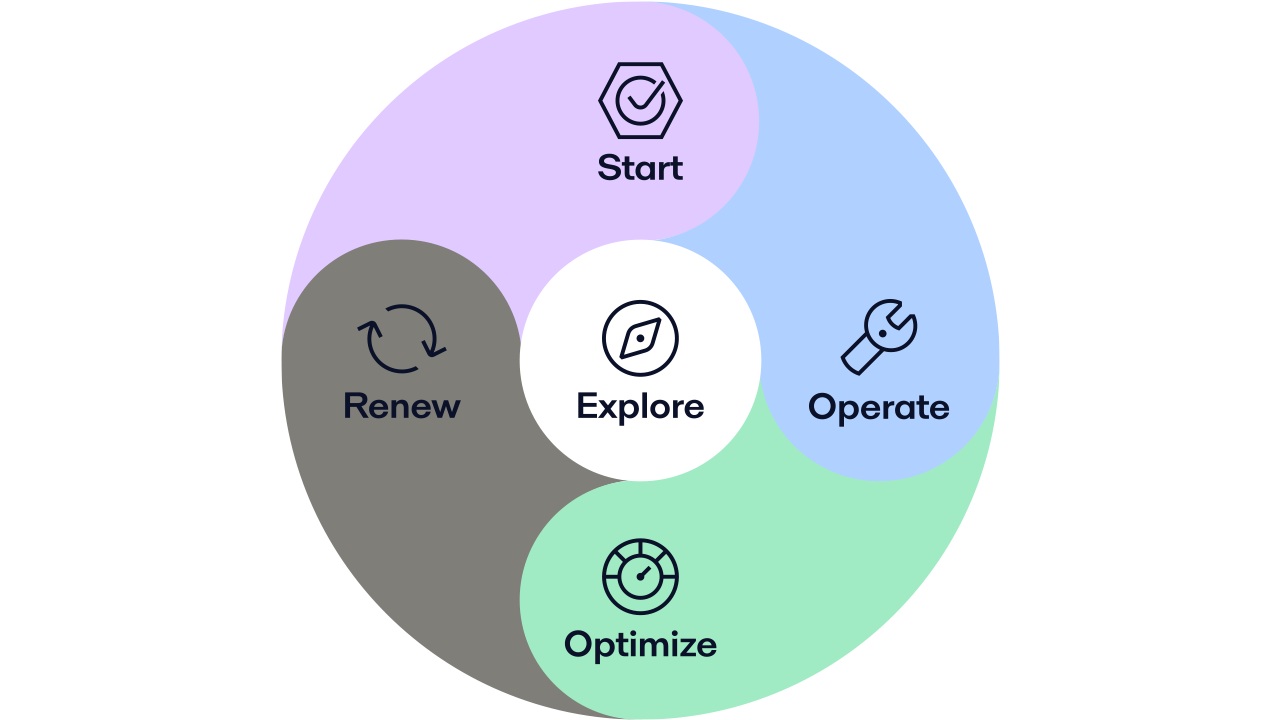

- A circular approach – close partnership throughout the plant lifecycle, from initial equipment selection to maintenance, upgrades, and eventual replacement.

- A comprehensive service offering, delivered with full documentation and in compliance with nuclear industry standards.

- A global network of service centers and field service technicians for fast, local support.

- Service Agreements – complete, tailored service solutions for maximum reliability and predictable budgets.