Dairy processing

The dairy industry is an essential player in meeting global food demand. Alfa Laval provides dairy processing equipment that reduces energy and water consumption significantly while meeting the strictest safety and hygiene standards. Maximizing yield and quality, optimizing efficient cleaning and minimizing waste throughout the process are key drivers to success in this environment and Alfa Laval is an expert partner that can be trusted to deliver these operational necessities.

Driving the dairy processing industry forward

- Extended production uptime

- Less time on cleaning and maintenance

- Reduction in energy, water, and chemical consumption

- Superb Cleaning-in-Place (CIP) performance

- High levels of hygiene to meet and exceed the dairy processing industry’s strict standards

Driven by continuous innovation for more than a century, Alfa Laval provides dairy processing equipment and expertise that delivers solutions to improve product quality, yield, cleanability and waste reduction.

With deep roots in the industry, Alfa Laval is committed to working with its customers and partners to understand the industry’s challenges and find smarter, better, and more efficient ways to produce top-quality dairy products. Through close collaboration with our partners we help identify optimal upgrade opportunities throughout the process and the dairy processing equipment's lifetime, to ensure the very best performance.

Supporting dairy processing plants to operate sustainably and save on water, energy, and chemicals, while meeting the strictest safety and hygiene standards, is in the Alfa Laval DNA.

This paves the way for dairies to make the most of every resource and create top-quality dairy products – with the flexibility and confidence to seize new opportunities in the market.

With Alfa Laval equipment, dairy processing industry customers will benefit from unique solutions, with innovative designs, that deliver:

Alfa Laval adds value across all applications in the dairy industry

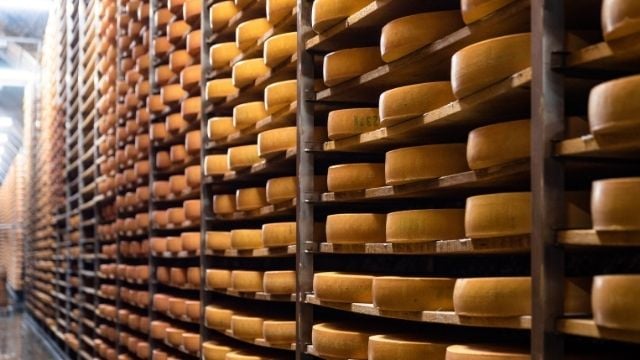

Whether it is processing butter and spreads, cheese or ice cream, Alfa Laval equipment and expertise is world-leading in delivering sustainable, efficient operations across all dairy applications. With a history steeped in dairy, starting off with milk and cream separation more than a century ago, Alfa Laval has branched out across the industry to process whey, casein and lactose and support customers in producing everything from yogurt and cultured milk to cultures and starting cultures, developing a comprehensive range of components that ensure better yields, smarter use of resources, and more efficient workflows.

Water circularity solutions

Across the globe there is a focus on water use like never before as the impacts of climate change take hold, and for dairies this presents a significant challenge – but also a huge opportunity.

With its industry-leading technology and expertise, Alfa Laval is joining forces with producers to put dairies on the journey towards water-positive production, challenging itself and its customers to develop solutions where operations can actually provide water to communities rather than taking it away.

The cutting-edge separators, decanters and membranes from Alfa Laval’s portfolio are already in use in dairies across the world, maximizing the volume of process water that can be recirculated for cleaning, cooling and more, and minimizing the flow that disappears down the drain as waste water.

Not only that, the COD that is separated from the treated process water, such as cleaning media, proteins and fats, can be concentrated and used for other purposes such as biogas production, boosting even further the circularity, efficiency and economies of dairy operations.

Optimizing every step in your dairy manufacturing process

From raw milk to the finished dairy product, Alfa Laval products solutions are engineered to optimize every stage of processing, boosting yield, uptime, and product quality, while minimizing the use of energy, water, and chemicals.

Milk reception

Milk reception demands uptime and efficiency. That means products with high reliability, easy serviceability, and both operational and energy efficiency.

Increasing productivity while providing gentle raw milk handling is key during milk reception. Alfa Laval hygienic components ensure optimal and reliable pump range can result in substantial savings and efficiency gains.

Mixing and blending

Precise and uniform mixing and blending is essential in many applications, contributing to an effective process and a high-quality end product. Optimal results are achieved by a balance between power, control, and flexibility. Using an Alfa Laval Agitator with specially developed EnSaFoil impellers for fermentation use, reduce energy consumption and the absorption of heat by your product. Meanwhile the Alfa Laval Rotary Jet Mixer radically increases efficiency in applications such as flavoured, fortified, and recombined milk, whipped cream from vegetable oil, dairy powders and emulsifiers.

Pasteurization

Pasteurization processes demand high levels of safety, hygiene, and process control. The pasteurization of milk is a vital process, and compliance with relevant regulations and standards is essential. Following UHT treatment, aseptic conditions must be maintained. The quality of components is key, with good flow control and reliable and efficient heat exchangers playing a central role.

Fermentation

Getting the most from raw materials is essential in the production of cultured products and fresh and cured cheeses. Important issues include achieving maximum efficiency in continuous batching and maintaining hygienic processing conditions.

Buffer and storage tanks

Alfa Laval's comprehensive range of innovative hygienic components are key building blocks in dairy processes. During buffer storage, tank optimization is key. Alfa Laval’s ongoing mission is to secure hygienic conditions and optimize its customers’ dairy production.

Separation

Alfa Laval’s ultrafiltration, nanofiltration, and reverse osmosis membranes give excellent yields in pre-concentration and protein purification prior to evaporation and drying.

Concentration

Reducing waste and emissions is an essential aspect of concentration processes. Achieving a good operating economy requires control over components’ energy consumption, such as the efficient AlfaVap heat exchanger designed for rising film evaporation systems.

Cleaning-in-Place

Quality in CIP is essential in the dairy industry. Efficiency is the key, both in terms of cleaning results and the economy. The CIP economy is dictated by cost and time. Reducing waste is critical; correctly configured and efficient cleaning, pumping and heating equipment is needed to get the cleaning fluid properly out to work on the surfaces.