Seed oil processing

Soybean, canola, sunflower, corn, peanut or something else entirely? No matter what type of seed oil you process, Alfa Laval has refinery solutions to help you boost product quality and get the very most from your raw materials. From neutralization and bleaching to deodorization, dewaxing and more, we offer specialized seed oil processing equipment covering the entire process line. All of it engineered to increase your profitability with more sustainable and more cost-effective operations.

First in oil with Alfa Laval

- Reliable seed oil processing equipment covering all steps of refining for any type of edible seed oil

- Oilseed processing solutions for boosting capacity, limiting loss and increasing yield, creating new profitable possibilities

- Improved sustainability and reduced operational costs thanks to unique technologies for maximizing energy efficiency

- A partner with deep understanding of industry demands to help you increase product quality and meet all safety and environmental requirements

- Continuous separation innovation from the leading developer of centrifuge and decanter technology for over 100 years

Our oil refinery experts have worked closely with customers for decades, enabling us to better understand both the challenges and possibilities facing today’s seed oil processors. Contact us today to learn more about how our solutions and service offering can help you to achieve long-term, reliable and more profitable operation.

Happy customers

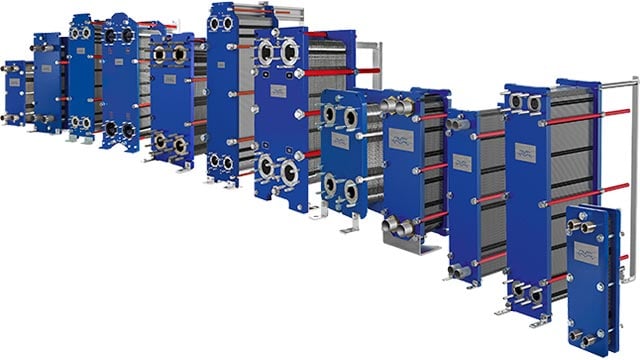

Key equipment used in our seed oil processing systems

Optimizing the edible oil process

Refining crude oil into edible oil requires deep process knowledge—from degumming, neutralization and dewaxing to bleaching, deodorizing and GE and 3-MCPD mitigation.