Animal blood processing

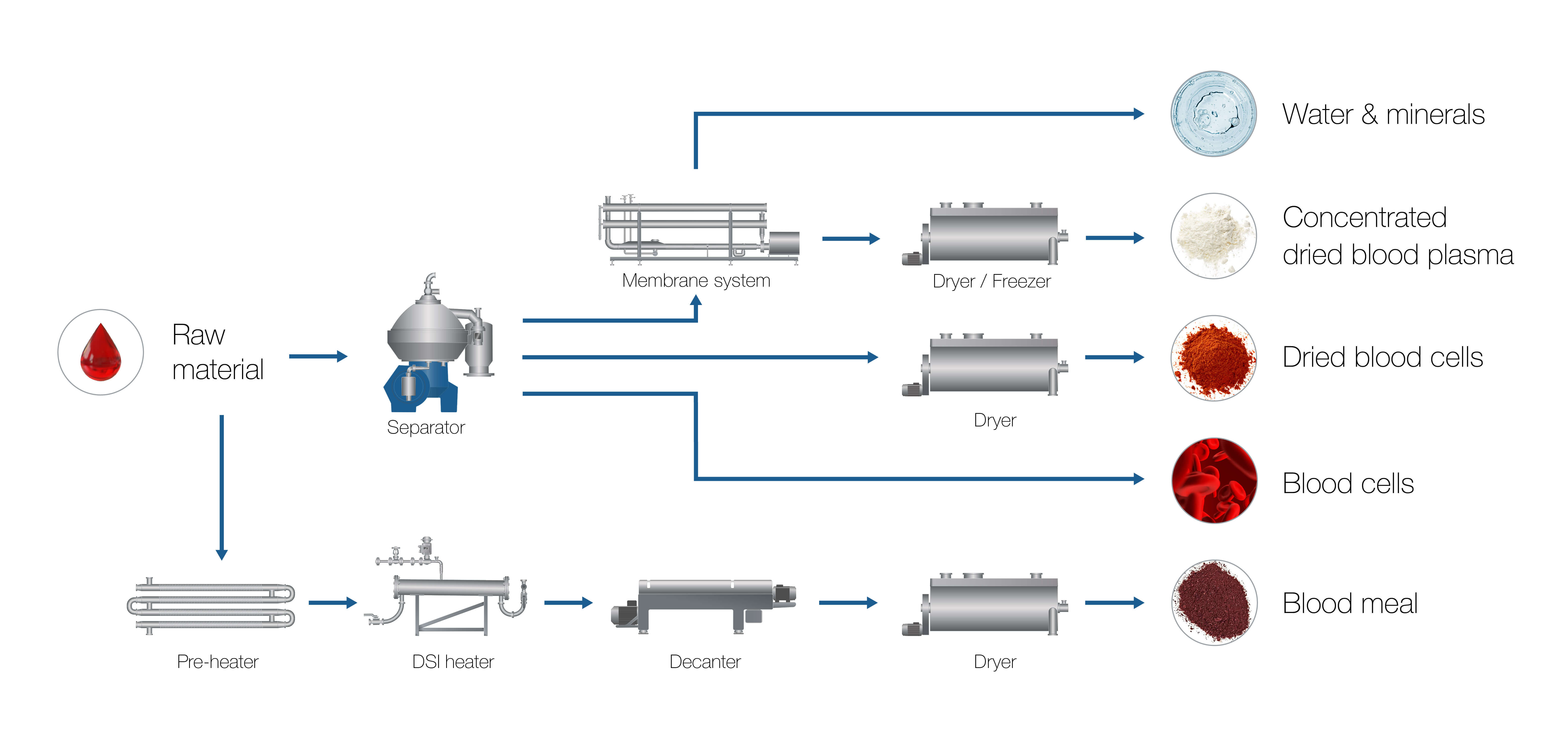

Animal blood from slaughterhouses can be processed into a range of high-value products suitable for human consumption. This is the most profitable way of utilizing the raw material but requires hygienic handling. When this is not possible, the blood can instead be converted into blood meal and sold as animal feed.

Alfa Laval provides key equipment and complete solutions for both plasma processing and blood meal production. Connect with our team of process experts to learn more.

Rich in valuable nutrients

Recoverable blood constitutes 3–4% of most animal’s total mass and is a rich source of nutritional and functional proteins. Its high protein concentration makes it an important and profitable, yet often underutilized and overlooked, protein source.

By separating the red blood cells from the plasma, these fractions can be further processed into a great number of different products. The red blood cells are usually dried and used for non-edible applications.

The plasma constitutes up to 60% of the raw blood and holds the highest commercial value. This fraction can be further processed into various plasma products and derivatives, which are used in the food and pharmaceutical industries, for sports nutrition, in cosmetics, and as cell culture media, among other applications.

Separation of plasma from blood by centrifugation, preconcentration, and drying

Plasma separation from blood is performed in two stages:

- First, the blood cells are separated from the plasma in a separator.

- The plasma proteins are thereafter preconcentrated in a membrane filtration system.

Alfa Laval offers a range of well-proven separators and membrane filtration systems (typically ultrafiltration units) for animal blood processing, along with heat exchanger solutions to ensure optimum temperatures during processing and intermediate storage, as well as fluid handling equipment. All our equipment is engineered to maintain strict hygiene standards and yield proteins of the highest quality.

Separation

Following the initial straining process, the raw blood can be heated to approximately 30 ºC before entering the separator in order to improve the separation of the plasma from the blood cells (haemoglobin).

The plasma fraction contains high-quality water-soluble protein and holds the highest value. In order to produce high-quality protein, it is crucial to minimize the shear forces acting on the blood cells during separation to avoid contamination and colouration of the plasma phase by ruptured red blood cells.

The blood cell fraction exiting the separator can be further processed in a separate bloodmeal processing line and sold for technical applications. Alfa Laval also possesses the know-how to assist in recovering a food-grade globin phase from the red blood cells.

Alfa Laval provides processing systems that convert technical-grade blood into blood meal with a significantly higher market value than standard meat and bone meals, see the Blood meal processing section below.

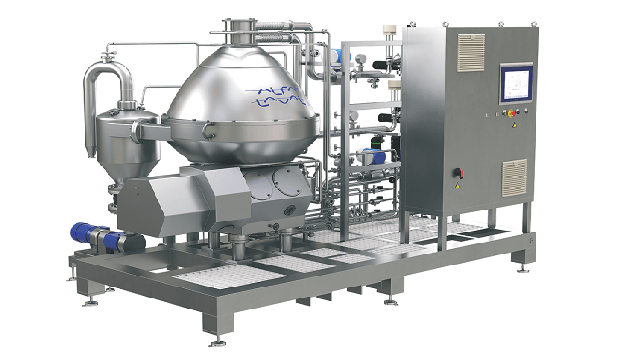

The HBPX fully hermetic separators are specifically designed for the separation of red blood cells and plasma in animal blood. They meet the toughest hygienic standards and ensure outstanding product quality and yield.

- High plasma yield

- Airless separation with minimum shear

- Excellent separation efficiency

- Gentle treatment of the product thanks to hermetic design, resulting in high-quality plasma

- Wear resistant

- Robust and reliable design

- Low energy consumption

- Up to 60% of the blood is recovered as plasma

Concentration and purification

During the second processing stage, the plasma is concentrated and purified in a membrane filtration system. By preconcentrating the plasma protein before final drying, the overall heat load and energy consumption are reduced, improving the final product quality.

Alfa Laval Pro-UF Plasma ultrafiltration systems are specially designed for the ultrafiltration of animal blood plasma.Here, the plasma passes multiple membrane stages, where water and salts are gradually removed from the plasma. The plasma initially contains up to 1.5% salt, but up to 90% of it can be removed in the ultrafiltration stage.

Depending on the requirements, such as limitations on salt content in the permeate water, nanofiltration or reverse osmosis separation can be utilized instead, whereby more salt is retained in the protein fraction.

Preconcentration in an ultrafiltration system increases protein levels from approximately 7% to 25%, depending on the quality of blood.

Alfa Laval Pro-UF Plasma ultrafiltration systems are specially designed torecover valuable plasma protein from bovine and pig blood plasma. The plasma proteins are concentrated when passing through several interconnected membrane stages. Minerals pass through the membrane with the water, which improves protein quality

- The ultrafiltration process increases protein purity by up to 92% without the use of diafiltration water

- Minimal CIP water consumption thanks to Alfa Laval GreenClean technology

- Low energy consumption.

- High degree of operational flexibility

- Wide range of equipment options

- The incoming plasma can be fed directly from the HSS, eliminating the need for an additional buffer tank

Temperature control

The high nutritional value of blood makes it particularly susceptible to bacterial growth. This means accurate control over the temperature of the raw blood and plasma is crucial to ensure the end product meets the stringent requirements set for food-grade ingredients.

In addition, precise temperature control is also required to prevent coagulation and equipment clogging.

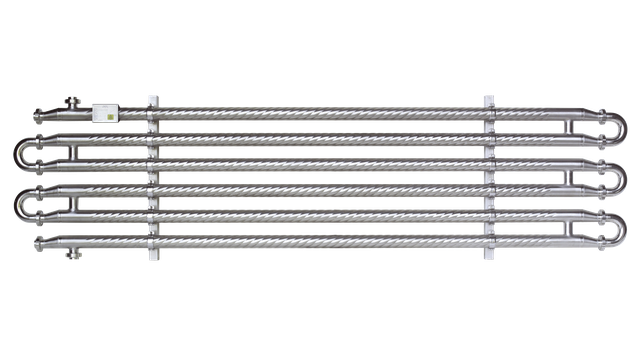

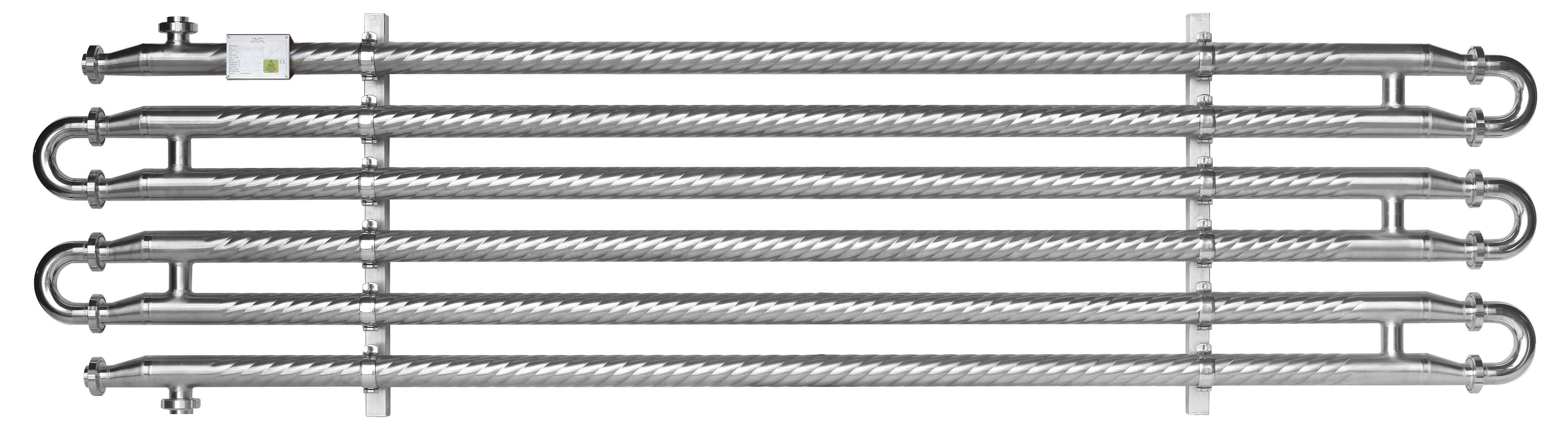

Alfa Laval’s ViscoLine range of tubular heat exchangers allows operators to control process temperatures precisely and handle the raw material in the most gentle manner.

AlfaBlood

Alfa Laval’s AlfaBlood system is a complete solution for the separation of red blood cells and plasma and the further fractionation and concentration of plasma protein. An AlfaBlood system provides an integrated approach to the process and can process virtually all kinds of water-free, strained blood. Characterized by high operational reliability and gentle product handling, AlfaBlood systems are ideal for blood fractionation.

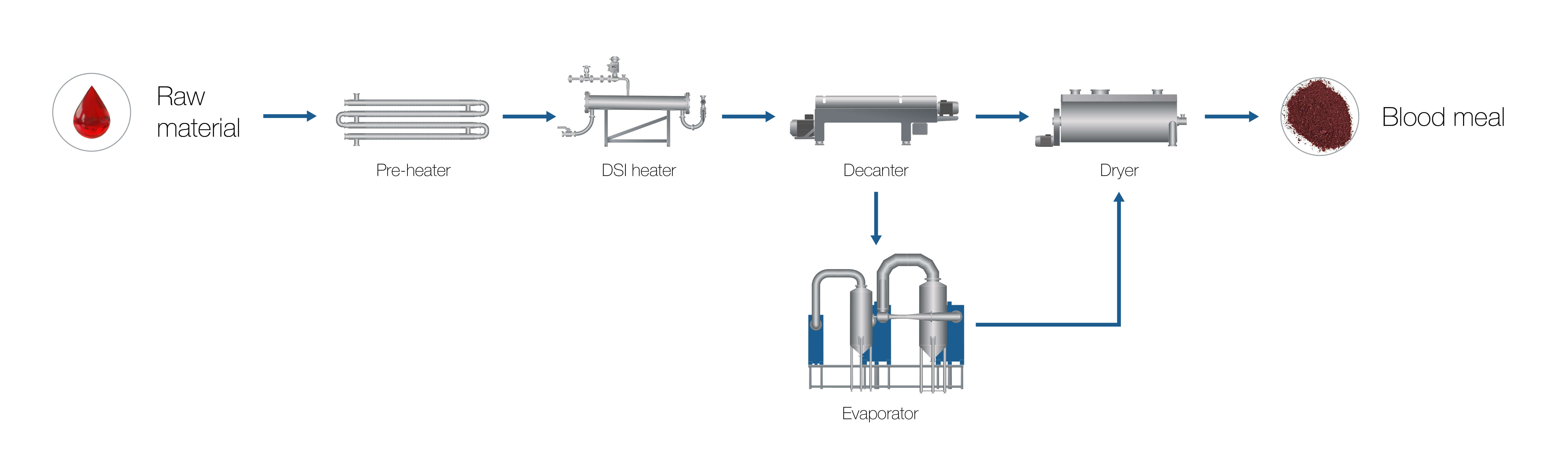

Blood meal production with Alfa Laval Centriblood

Blood that cannot be collected in a hygienic manner or find use in food-grade applications can be processed into blood meal in an Alfa Laval Centriblood system in a highly energy efficient manner.

The raw material is first preheated to 45°C in an Alfa Laval ViscoLine VLM tubular heat exchanger, using the decanter blood water as the heating medium. The blood is thereafter coagulated in an Alfa Laval DSI blood heater before being dewatered in a decanter.

The blood water, containing the minerals and trace proteins, is discharged. It is also possible to concentrate the blood water in an AlfaVap evaporation system. This significantly reduces the BOD load in the wastewater. The concentrate can be disposed of separately or added to the dewatered blood meal before the drying stage.

Finally, the blood meal is dried. The standard method is indirect heated coil contact drying, but flash drying is also possible when improved digestibility is required.

Hygiene management

Raw blood is heated to a temperature ranging from 25°C to 45°C during processing, posing a significant risk of bacteria growth if hygiene measures are insufficient.

When producing edible blood protein for human consumption or for use in pet food, meticulous hygienic procedures must therefore be in place to prevent contamination.

All Alfa Laval equipment used for animal blood processing is designed to provide effective end-to-end hygiene management, including quick and resource-efficient cleaning.

Complete service solutions for uninterrupted operations

With Alfa Laval as your service partner, you have direct access to qualified assistance and genuine spare parts whenever required. Our global network of service offices offers professional support ranging from troubleshooting and routine maintenance to advanced performance audits and predictive maintenance.

Through our remote services, we provide immediate assistance through digital channels. If you need on-site support, we will quickly dispatch field technicians to your site.

Alfa Laval offers full support for both individual components and entire process lines. Combining our reliable products and systems with Alfa Laval services is the best way to ensure performance and uptime.

For maximum return on your investment, we recommend entering an Alfa Laval Service Agreement. This fully customized service solution simplifies budgeting and maximizes performance and uptime. While you concentrate on your daily operations, we manage the planning, procurement, and execution of the required service measures.