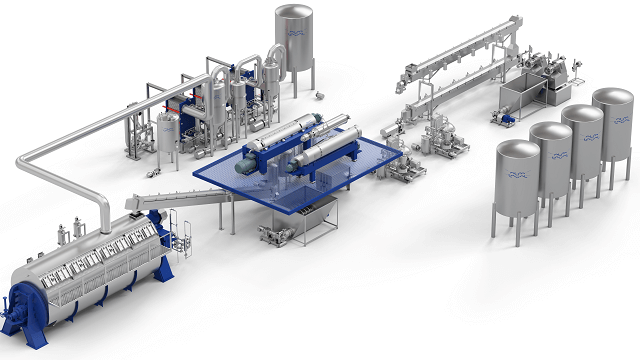

Dry rendering process

Animal by-products unsuitable for human consumption still have significant economic value. With dry rendering, these by-products can be transformed into raw materials for pet food and animal feed, biofuel, and technical products such as lubricants and ingredients for glue.

Alfa Laval supplies a range of proven components and subsystems for dry rendering systems. They are perfect for upgrading existing processing lines to improve capacity, operating cost, energy consumption, quality, and yield.

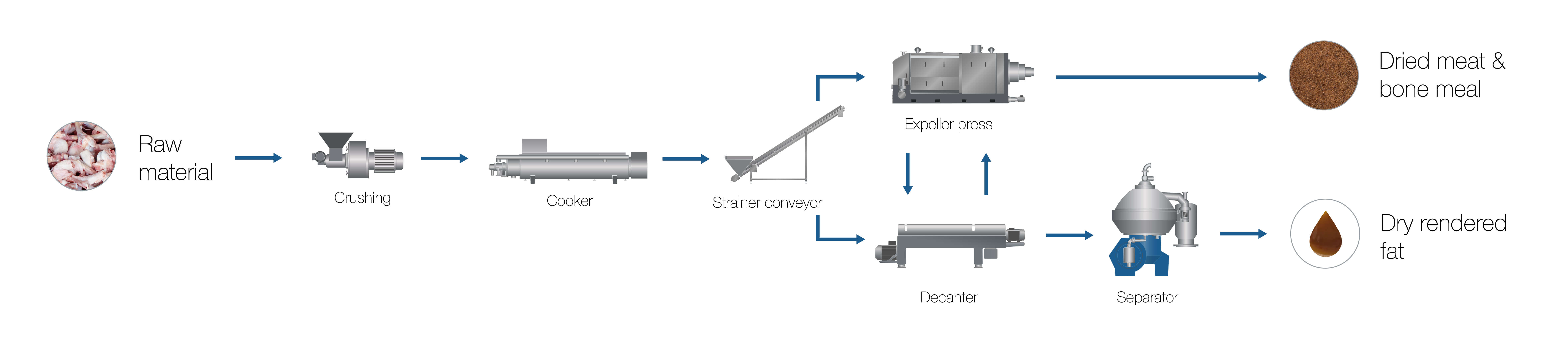

Dry rendering processing systems

A dry meat rendering process divides non-edible animal by-products into four fractions: meat and bone meal, fat, minerals, and water. The meat-and-bone meal is often used as an ingredient in pet food and animal feed, while the fat can be used in animal feed, technical applications, or as a raw material for biofuel production.

Crushing and cooking

In the initial phase of the dry rendering process, the raw material undergoes crushing and is thereafter heated in an indirectly heated cooker. The temperature is regulated, ensuring it is high enough to melt the fat but low enough to maintain high protein quality. During cooking, the fat and protein separate from the bone material, and almost all the water in the raw material is evaporated. The result is a mixture consisting of mainly bone fragments, protein, and fat.

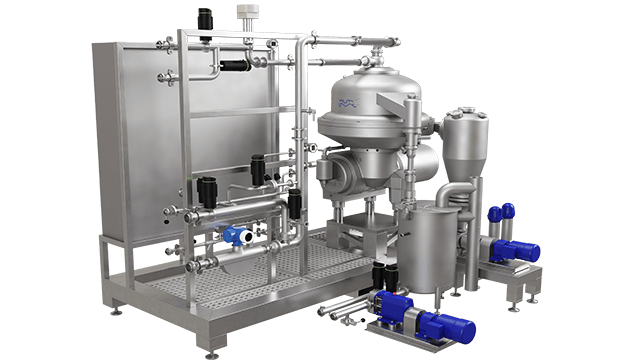

Separation and purification

Most of the fat is drained from the meat-and-bone mixture, which is fed to an expeller press where the residual fat is squeezed out.

The liquid phase, consisting of fat and some solids, is sent to a decanter, where the remaining meat fines are removed. These are then either added to the press cake or the press infeed. The fat may contain some residual fines, which can be extracted in an oil polisher to reduce the impurity level to less than 0,15%.

The defatted press cake is subsequently cooled, milled, and labelled as bone meal or meat and bone meal.

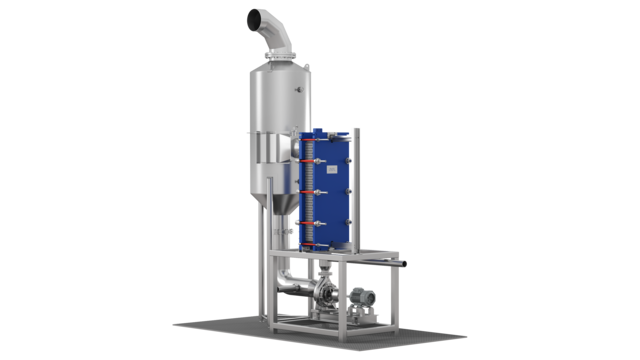

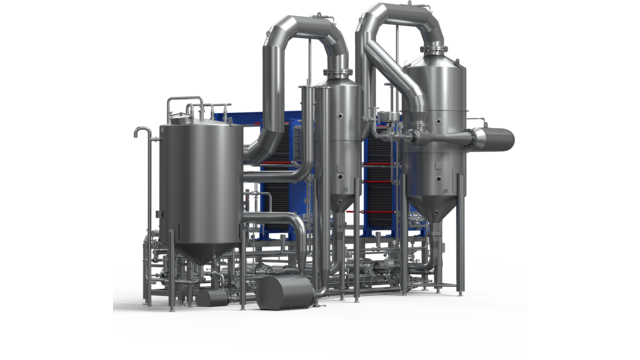

Maximize energy efficiency and yield with Alfa Laval Dry Rendering Optimizer

Energy for water removal constitutes a substantial expense in a dry rendering plant. The Alfa Laval Dry Rendering Optimizer is an easily installed upgrade that reduces energy consumption by up to 40% while improving product quality. The upgrade can be seamlessly integrated into any existing dry rendering line, providing a straightforward way to reduce energy costs and improve overall plant sustainability.

Alfa Laval Dry Rendering Optimizer also makes it possible to convert an existing dry rendering process to a Centriflow wet-rendering process. This improves fat quality and yield, raises protein levels in the meat and bone meal, and lowers energy consumption.

Raw material for biofuel and HVO

The growing HVO and biofuel markets have caused a strong increase in the demand for animal fat. Alfa Laval offers solutions that enable the purification of the fat from a dry rendering process to a level that meets the biofuel industry’s most stringent quality requirements. This opens new possibilities for selling fat at a higher market price and creating more value from your raw material.

The demands on the raw material for biofuel production are often high and include:

- High-fat content

- Low levels of impurities

- Low moisture content

- Low levels of free fatty acids

- Consistent composition

Selling fat to biofuel and HVO producers is an attractive income source thanks to the high market price. Contact us to learn how you can take advantage of these possibilities.

Complete service solutions for uninterrupted operations

With Alfa Laval as your service partner, you have direct access to qualified assistance and genuine spare parts whenever required. Our global network of service offices offers professional support ranging from troubleshooting and routine maintenance to advanced performance audits and predictive maintenance.

Through our remote services, we provide immediate assistance through digital channels. If you need on-site support, we will quickly dispatch field technicians to your site.

Alfa Laval offers full support for both individual components and entire process lines. Combining our reliable products and systems with Alfa Laval services is the best way to ensure performance and uptime.

For maximum return on your investment, we recommend entering an Alfa Laval Service Agreement. This fully customized service solution simplifies budgeting and maximizes performance and uptime. While you concentrate on your daily operations, we manage the planning, procurement, and execution of the required service measures.