Hydrolysis of meat and poultry byproducts

Add value to your edible or feed-grade byproducts with an Alfa Laval hydrolysis system. This presents a lucrative alternative to wet or dry rendering your byproducts into a meat and bone meal.

Alfa Laval offers a range of components used in hydrolysis processes, as well as complete processing lines for both enzymatic and thermal hydrolysis.

Reach out to our hydrolysis experts to learn more.

High-quality protein hydrolysates

Hydrolysis enables you to process edible byproducts from slaughterhouses into edible proteins with high nutritional and economic value. The hydrolysis process – whether enzymatic or thermal hydrolysis – transforms proteins in the raw material into water-soluble peptides with an attractive flavour profile.

Hydrolysed protein is used in a wide range of products:

- Dietary drinks and protein bars, etc.

- Easy-to-digest food for the elderly and children

- Soup and savoury products

- Noodle sachets

- Injection brine

- Weaning and starter diets for livestock

- Growth enhancers for livestock

Production of hydrolyzed proteins

Alfa Laval offers two different hydrolysis systems:

- Hypro Enzymatic

- Hypro Thermal

Hypro Enzymatic is best suited for soft materials, generating a liquid protein solution with high digestibility and attractive flavour. Hypro Thermal is ideal for raw materials containing larger pieces of bone material, transforming it into a flavourful broth.

Hypro Enzymatic

Hypro Enzymatic is a semi-continuous, low-temperature process based on enzymatic hydrolysis of protein. Initially, the raw material is ground into small pieces before being transferred into a hydrolysis tank (digestor) and heated to around 55°C. The enzymes are added, and the warm blend is allowed to react for a period of time. The reaction time depends on the chosen enzyme and the desired properties of the end product.

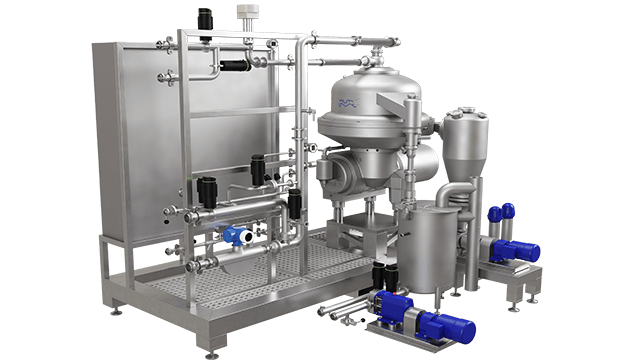

The actual digestion process is performed in batches, while the remaining steps are continuous. Downstream of the hydrolysis tanks, the blend is heated to deactivate the enzymes. The higher temperature also enhances the efficiency of the subsequent stage, where bone particles are removed in an Alfa Lava paddle refiner, and the fat, solids, and liquid fractions are separated in a decanter.

Removing the fat in the blend prior to the enzyme digestion stage increases the enzyme effect and the yield. Alfa Laval Oil Plus decanters are specially designed for the extraction of oil and fat and are the best choice for this task. The fat fraction is purified in a separator and, if required, vacuum dried.

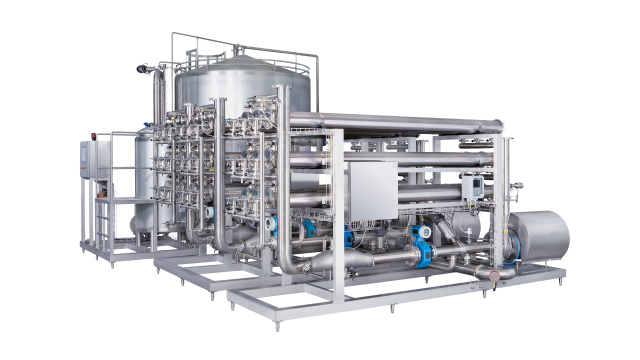

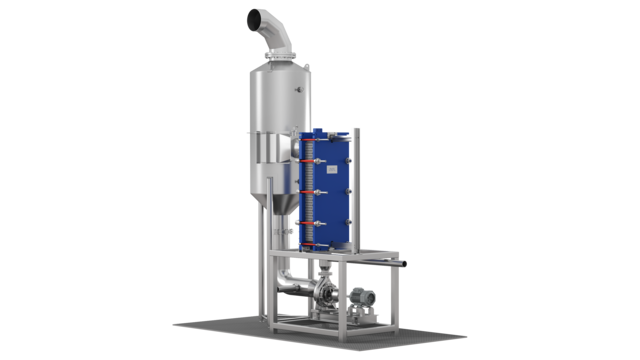

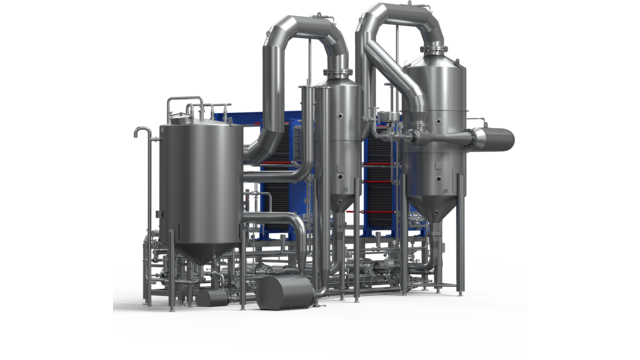

The liquid broth can be defatted using an Alfa Laval skimmer centrifuge and further purified in ultrafiltration and nanofiltration membranes to manufacture nutritional protein concentrates and isolates. Water is removed from the final liquid using Alfa Laval AlfaVap and AlfaFlash evaporation systems before the product is dried in either a scraped drum dryer or a spray dryer.

Hypro Thermal

Hypro Thermal utilizes pressure cooking to hydrolyse the proteins. Subjecting the bones and connective tissue to a high temperature over an extended period of time in the pressure-cooking vessel hydrolyses the collagen and breaks down the bone and connective tissue structure to a flavourful broth. The steps after the pressure-cooking vessel are similar to those for Hypro Enzymatic.

We invite you to our test facilities, where we assist you in testing and documenting your process, as well as selecting the right equipment for it.

Complete service solutions for uninterrupted operations

With Alfa Laval as your service partner, you have direct access to qualified assistance and genuine spare parts whenever required. Our global network of service offices offers professional support ranging from troubleshooting and routine maintenance to advanced performance audits and predictive maintenance.

Through our remote services, we provide immediate assistance through digital channels. If you need on-site support, we will quickly dispatch field technicians to your site.

Alfa Laval offers full support for both individual components and entire process lines. Combining our reliable products and systems with Alfa Laval services is the best way to ensure performance and uptime.

For maximum return on your investment, we recommend entering an Alfa Laval Service Agreement. This fully customized service solution simplifies budgeting and maximizes performance and uptime. While you concentrate on your daily operations, we manage the planning, procurement, and execution of the required service measures.