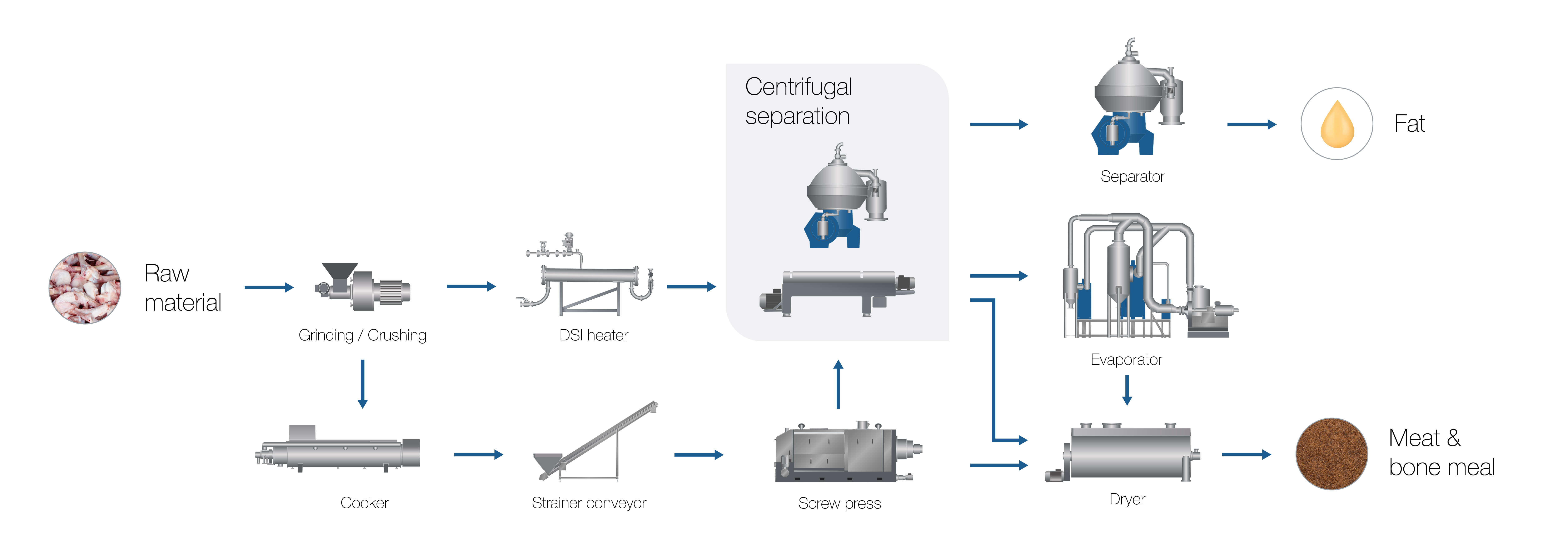

Wet rendering process

Maximize the value of your protein and fat products with wet rendering solutions from Alfa Laval. Our unique wet rendering process offers many advantages compared to traditional dry and wet rendering, including higher fat yield, protein content and product quality, reduced energy consumption, a more space-efficient compact installation, and the possibility to produce food-grade products.

We can support you with expert advice and a comprehensive range of solutions. Contact us today to learn more.

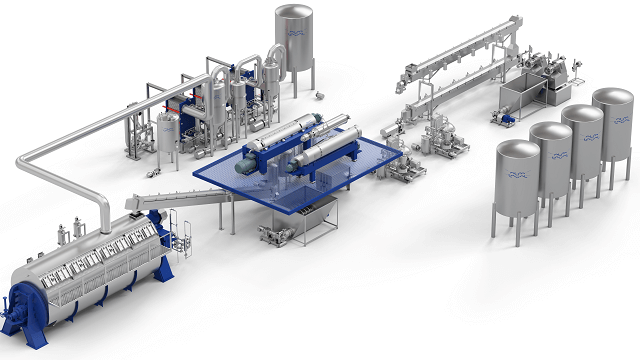

Alfa Laval wet rendering systems

Alfa Laval’s Centriflow hard and soft tissue rendering systems offer continuous, low-temperature processing for a wide range of meat and poultry by-products, delivering high yield, outstanding product quality, and exceptional energy efficiency. Thanks to its compact design, an Alfa Laval wet rendering plant requires minimal installation space and can easily be fitted into an existing animal rendering plant.

Grinding

In the initial stage of the process, the raw material undergoes grinding to facilitate heating and release of the fat.

Heating

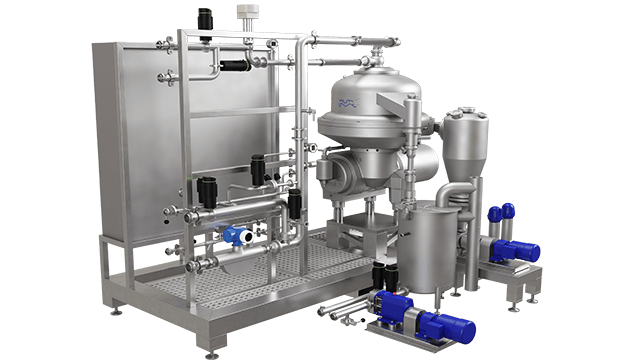

Next, the raw material is heated in a DSI hard or soft tissue heater using direct steam injection. The steam is injected into the raw material through a set of optimized nozzles, ensuring the fastest possible heating. The rapid heating and precise temperature control allow for fast coagulation and inactivation of bacteria and enzymes, thereby ensuring maximum fat and protein quality. In addition, the whole heating process takes place under airless conditions to reduce the risk of oxidation and release of odours and ensure sanitary conditions. The heat induces the release of fat from the solid meat and the protein to coagulate, facilitating the subsequent separation.

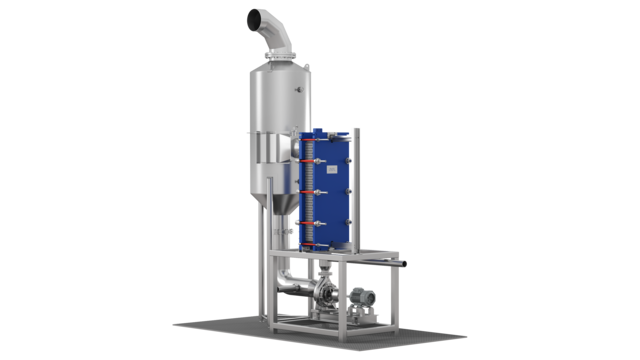

Separation, concentration, and purification

The heated material is separated in a multistage decanter and separator arrangement, where the heated product is separated into the fat, solids, and stickwater fractions. Our patent-pending Oil Plus technology, in combination with a skimmer centrifuge, makes it possible to reduce the fat level in the protein meal to below 7%, boost the protein content in the meat and bone meal, and increase the yield of high-value fat.

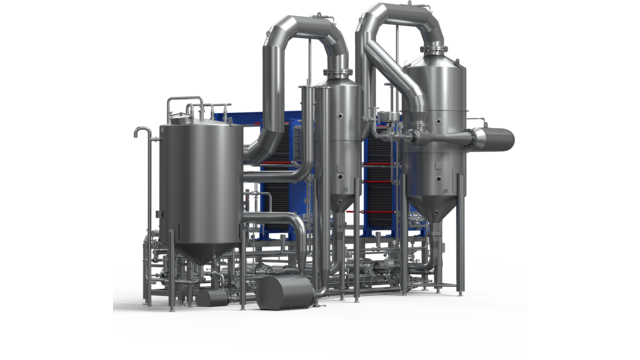

The stickwater is concentrated in an evaporation system and mixed with the solids phase before being sent to the dryer unit. The evaporation system can operate on waste heat from the dryer, effectively reducing the energy consumption of the rendering plant.

Since the fat is extracted at temperatures below 100°C, any plastic polymer contaminants will not melt and dissolve. Instead, they will exit the decanter with the oil phase and can thereafter easily be removed using our special separation screens. The need for expensive, subsequent refining of the fat is, therefore, very limited. The fat phase can undergo further processing in a separator to reach more than 99,5% purity.

Minimal energy consumption

Alfa Laval wet rendering systems have significantly lower energy consumption than a dry rendering system, as most of the water is removed mechanically in a decanter instead of being boiled off in a cooker.

The stickwater is concentrated in Alfa Laval evaporators, utilizing waste heat from the final dryer to minimize energy consumption. Alfa Laval evaporators can handle highly concentrated, viscous fluids, thereby minimizing the need for subsequent drying.

Using waste heat to evaporate the majority of the water is the most energy-efficient solution. We can also offer systems fitted with thermal or mechanical vapor recompressing. For example, in case a hot air dryer is used instead of a disc dryer for the final drying due to special product quality demands.

Raw material for biofuel and HVO

The growing HVO and biofuel markets have caused a strong increase in the demand for animal fat. The fat produced in a wet rendering system is of very high quality and can be purified to more than 99%. This makes it an attractive raw material for a range of biofuels, including HVO, presenting new possibilities to sell fat at a premium price.

The demands on the raw material for biofuel production are often high and include:

- High-fat content

- Low levels of impurities

- Low moisture content

- Low levels of free fatty acids

- Consistent composition

The market price for raw materials meeting the specifications is high, making this an attractive income source. Contact us to learn more about our processing and refining solutions for biofuel applications and how you can benefit from them.

Complete service solutions for uninterrupted operations

With Alfa Laval as your service partner, you have direct access to qualified assistance and genuine spare parts whenever required. Our global network of service offices offers professional support ranging from troubleshooting and routine maintenance to advanced performance audits and predictive maintenance.

Through our remote services, we provide immediate assistance through digital channels. If you need on-site support, we will quickly dispatch field technicians to your site.

Alfa Laval offers full support for both individual components and entire process lines. Combining our reliable products and systems with Alfa Laval services is the best way to ensure performance and uptime.

For maximum return on your investment, we recommend entering an Alfa Laval Service Agreement. This fully customized service solution simplifies budgeting and maximizes performance and uptime. While you concentrate on your daily operations, we manage the planning, procurement, and execution of the required service measures.