Soap treatment and Tall oil production

Alfa Laval has a long history in tall oil production for food products, adhesives, varnishes, inks or drilling fluids. Our highly efficient centrifugal separators are used to radically increase yield and product quality in a sustainable process compared to conventional technology. The same technology can also be applied to separate soap from black liquor to produce high-quality crude tall oil.

Significantly higher tall oil yields than conventional technology

- More than 97% yield of high-quality crude tall oil

- Rapid and efficient separation process

- Compact design and space-saving footprint

- Fully automated including cleaning in place (CIP)

- Reduced sulfuric acid consumption per m3 tall oil

Alfa Laval has more than 70 years of experience in centrifugal separators for tall oil production. Today, our separators are at the heart of many tall oil systems worldwide where their high-yield separation efficiency and sustainable operation are helping meet demand in a market where supply is limited.

Innovation through proven technology

Alfa Laval has long experience in supplying centrifugal separators for tall oil production which originates back with the, at that time, acquired company Celleco in the 1950s. Since then, Alfa Laval centrifugal separators function as the heart of many tall oil systems worldwide.

Whether used as a component in food products, adhesives, varnishes, inks or drilling fluids, fuels, high-quality crude tall oil is in demand while the supply is limited. Therefore, it is important to get most out of the extractives with highest yield possible. This is enabled by efficient separation.

Tall oil production and soap separation

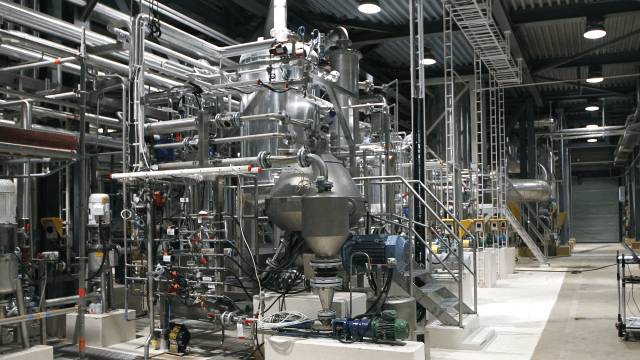

The long experience we have at Alfa Laval helps us understand the need for process efficiency in tall oil production plant. In partnership, we supply Alfa Laval platforms based on centrifugal separators that combine several technologies into complete systems for crude tall oil production and soap treatment:

- Tall oil production plant to process soap to a high-quality crude tall oil

- Black liquor soap separation to remove soap from black liquor

For tall oil systems with high lignin and solids content (a typical result of poor soap skimming), a decanter centrifuge can be used upstream of the centrifugal separator to further improve separability.

Higher efficiency, smaller footprint, increased quality

Centrifugal separators eliminate the need for large volume holding tanks and therefore reduce footprint while increasing separation efficiency. They also reduce process residence time from days to minutes, resulting in a fresher soap, better product quality and higher yields.

The Alfa Laval tall oil production and soap separation process are very high yield and, because they are a closed-system design, have a low environmental impact. You can look forward to a significant reduction in sulphuric acid consumption compared to conventional technology, which can help improve your mill’s sulphur balance.

Alfa Laval has the broadest offering of separators – each fully optimized for its duty. Combined with our worldwide service network, you can count on reliable, high-quality and sustainable operation throughout the long lifetime of your equipment.

How the PX separator works

The tall oil mixture to be separated is fed into the separator bowl from the bottom through a hollow spindle and enters the disc stack. The heavy phase and heavy sludge are forced towards the periphery of the bowl, while the light phase flows towards the center of the bowl, from where it is pumped out for further processing. The heavy phase is led over a top disc into a chamber where an adjustable paring device pumps it out of the separator. Sludge collects in the sludge space and is discharged automatically at pre-set intervals. The discharge uses a hydraulic system, which, at preset intervals, forces the bottom of the sliding bowl to drop down, thus opening the sludge ports at the bowl periphery. The sludge is collected in the frame and leaves the centrifuge via a cyclone.

Case stories

Alfa Laval separators optimize tall oil production

Increased yield, higher product quality and a more sustainable process were some of the improvements Swedish pulp producer Södra Cell experienced when upgrading the tall oil plant in its Värö mill to a TOPP5000 system. The new plant was supplied by HEAD Engineering and is based on Alfa Laval high-speed separators.

How can we help you?

If you have any questions about Alfa Laval’s solutions to sustainably optimize tall oil black liquor and other vital processes in pulp production, get in touch with us now.