Hong Kong wastewater treatment plant increases energy efficiency and reduces carbon emissions with Decanter upgrade

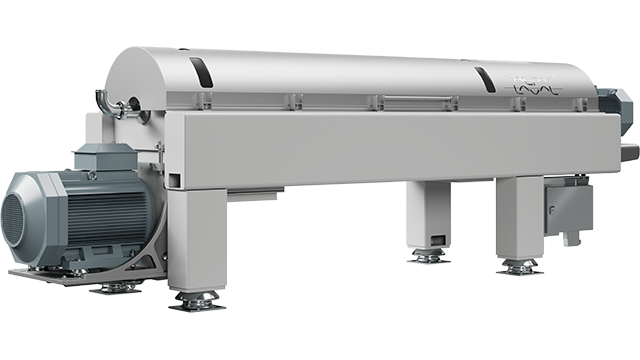

A sharp focus on energy efficiency was central to the Hong Kong Drainage Service Department’s decision to upgrade its decanter centrifuge technology at the Sha Tin Sewage Treatment Works; it was key in its selection of Alfa Laval’s Aldec G3 equipped with VecFlow™ technology to achieve this aim.

DATE 2025-07-10

The Sha Tin Sewage Treatment Works is situated at the mouth of the Shing Mun River and covers 28 hectares. Run by the Drainage Services Department, it serves a population of 700,000, producing approximately 280,000 cubic metres of sewage per day and total 120 tonnes of sludge per day.

The replacement,of two Alfa Laval Aldec 706 decanters with Aldec G3 VecFlow models for sludge dewatering is now generating a 40% energy reduction and lowering overall CO2 emissions by 285 tonnes annually as part of an ongoing sustainability strategy at the Sha Tin site.

“Since 1998, we have been on a journey to change the face of wastewater treatment to improve the water quality and optimize the operation,” says a spokesperson for the Sha Tin Sewage Treatment Works. “In the 1980s, we had issues with red tide during spring; an algae formation of a reddish colour that can cause health issues.”

The more recent supply constraints of fresh water in Hong Kong have prompted the Sha Tin Sewage Treatment Works to look intensely at how they can optimize energy consumption and waste production to minimize the impact on the surrounding environment.

“Increasing the energy efficiency of our operation with the Alfa Laval decanters, reducing electricity consumption throughout the sewage treatment process and generating electricity from biogas produced in the digesters on site are some of the measures we have implemented to minimize our impact on the environment and reduce carbon emissions,” concludes the spokesperson at Sha Tin Sewage Treatment Works.

“We have eight dewatering and five thickening machines at this site,” Regional Sales Manager Raymond Yau explains. “The customer is in the process of upgrading. So far, they have replaced two dewatering machines with the Aldec G3 VecFlow. The VecFlow feed zone injects sludge in a way that has minimal effect on the flow inside the decanter bowl; reducing turbulence by more than 44% and lowers overall power consumption.”

“The interesting thing on this site is that we have the old machines, and we have a new slimline G3 machine and the VecFlow so we can measure them side by side,” continues Steen Rosenbom, Global Sales, Water & Waste, BU Decanters. “Raymond has built an excellent relationship with this customer over the years, enabling us to do this detailed measuring. Now that we have analysed the results, we can see a power saving of 40% and a slight improvement in cake dryness; but the main driver for the customer is the power saving from upgrading to the decanter with VecFlow.”

With the power saving, the decanter uses only 5% of electricity generated in a combined heat and power (CHP) plant that burns biogas collected during the sludge treatment process.

“The output of electricity from the CHP is not enough for the whole plant but reducing the energy consumption of the decanters by 40% plays a part in cutting the overall energy requirements at the plant – saving money and lowering CO2 emissions,” Steen concludes.

As part of a broader focus on sustainability at Sha Tin Sewage Treatment Works, a maximum of 1,000 cubic metres of treated sewage water at the plant is reclaimed every day using filtration, membranes, and reverse osmosis technologies. Although not suitable for drinking, this water is fed into the system to meet non-potable needs such as plant cleaning, irrigation, and chemical dilution.

Highlighted Technologies

Emissions savings

Close to zero carbon emissions in Alfa Laval decanter assembly because all Alfa Laval decanter manufacturing sites run exclusively on sources of renewable energy

By securing a 20% reduction in the energy consumption, the Aldec VecFlow solution has reduced the emissions of CO2-equivalent by 285 tonnes.

Total cost of ownership

The combined reduction in the consumption of energy and polymer has been reduced by more than 20%, and the payback time on the added VecFlow feature is less than 2 years. With this Total Cost of Ownership was reduced by an estimated 10%.

Clean water

By 2050, it will require another 30% of clean water to sustain life for the 11 billion people likely to inhabit our planet (UN, 2019). Hong Kong is already one of the megacities at risk of severe water shortage. It may not be able to continue to rely on water supplies from the Dongjiang River to provide the bulk of its freshwater supplies. Also, the city lacks natural or constructed reservoirs for collecting rainwater.

Background: In 2022, Hong Kong’s annual freshwater consumption was 1,027 million m3. The Sha Tin Water Treatment Work’s design capacity is at 1.227 million m3 a day or 447.9 million m3 a year, which equals 19% of the total water consumption in Hong Kong.