MultiJet

The Alfa Laval MultiJet rotary jet heads removes hard-to-clean residues from surfaces in harsh process environments in the paint, starch, home care, chemical, pulp and paper, ethanol, oil and other industries. Its robust construction ensures durability, while its worm gear design provides the high torque required for operational reliability. The result is exceptional tank cleaning efficiency, better end-product quality, greater overall output and reduced operating costs.

Cost-effective rotary jet heads tank cleaning equipment for industrial tank cleaning duties

- Ensures uptime thanks to robust handling of hard-to-clean residues

- Increases productivity thanks to 60% faster, more effective cleaning cycles than comparable spray ball tank cleaning equipment

- Saves up to 70% in cleaning costs due to more efficient use of water and cleaning media

- Eliminates the need for manual tank cleaning; no tank entry is required

- Hygienic safety by reliable and predicable cleaning performance

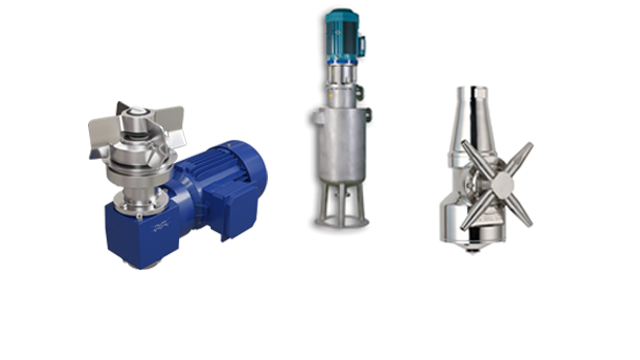

Cleaning industrial process tanks calls for rugged, reliable and effective tank cleaning equipment that can handle harsh operating environments and thoroughly clean tough residues. The Alfa Laval MultiJet rotary jet heads spray ball tank cleaning equipment are ideal for tank cleaning duties involving the removal of the toughest residues from industrial tanks – even those situated in potentially explosive atmospheres. Available as two- and four-nozzle versions, it is available in various sizes and configurations to clean tank sizes with capacities ranging from 5 m3 to 1,000 m3.

The Alfa Laval rotary jet head tank cleaning machines proved very efficient for cleaning the interior of solvent-based paint production tanks in ATEX zone environments using recovered solvent as the cleaning media.”

– Morten Schaarup, Project Manager, Hempel A/S, Denmark

How does the MultiJet rotary jet heads work

The high-impact jet stream from the Alfa Laval gamajet covers the entire surface of the tank interior in a successively denser 360° pattern. This achieves a powerful mechanical impact with a low volume of water and cleaning media.

Upon achieving the full cleaning pattern, the spray ball tank cleaning jet head will begin a new cleaning pattern and will continue to perform the next full cleaning cycle.

Safe, efficient and reliable tank cleaning

Increase tank cleaning operational reliability with the robust design of Alfa Laval MultiJet rotary jet head tank cleaning machines. The MultiJet spray ball tank cleaning equipment improves tank cleaning efficiency, speeds cleaning cycle times, and reduces energy, water, and cleaning media consumption for virtually any tank size and configuration.

Ensure efficient distribution of rinse water to all interior tank surfaces with the MultiJet’s optimized 360° high-impact jet spray pattern. Compared to the more expensive and time-consuming cleaning methods of soaking in chemicals or manual cleaning, the MultiJet quickly and effectively removes tough residues from tank interiors after completing every production cycle.

Proven performance reliability and long service life

Alfa Laval MultiJet rotary jet head tank cleaning machines are based on proven technology that provides reliable and repeatable cleaning performance and long service life. For optimal cleaning performance, use an operating pressure between 5 and 12 bar.

Cost-effective maintenance with minimal downtime

Improve process performance, increase tank cleaning efficiency and extend the service of tank cleaning equipment. Parts replacement is quick and easy using spare part service kits

Close at Hand catalogue

The hygienic equipment product catalogue "Close at hand" includes product leaflets, links to animations, brochures and lists for ordering purposes.

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Service

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Learn more about our service offer Troubleshooting

Serial number search Certification

Please contact us with any queries or questions.

Visit the Application & Innovation Centre

Do you want to identify the optimal equipment for the job and discover tangible savings before deciding on upgrades? In the Alfa Laval Application & Innovation Centre, you can do just that.

Optimize™ by Alfa Laval

Optimize™ by Alfa Laval boosts your existing processes and enables up to 90% savings on water, energy and chemicals with only small and no-risk investments.

Ten top tips - Tank Equipment

Here are some tips and service videos to show you how you can keep your tank equipment in tip top condition.

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Animations

Visit the animations site and take a look inside a product to see and understand how it works.