PX

The Alfa Laval PX oil separators are ideal for processing vegetable oils, lard, tallow, and fish oil. Designed for superior separation quality and higher yield, this oil centrifuge ensures gentle treatment of sensitive oils across degumming, neutralization, dewaxing, and washing in vegetable oil and animal fat refining industries. Premium quality centrifugal separators for small, medium, and large plant capacities. It delivers exceptional reliability in small to large-capacity plant operations.

Experience the benefits of PX range, Alfa Laval edible oil centrifuges

- Centrizoom technology for optimal handling of high viscosity media

- Bowl is made of high performance stainless steel for optimal resistance to metal fatigue and superior erosion protection

- Secure more uptime and save up to 400 kg per year in GHG emissions with Alfa Laval Erosion Liner

- Robust and easy to maintain

- The widest range on the market with refining capacities from 50 to 1500 tons per day

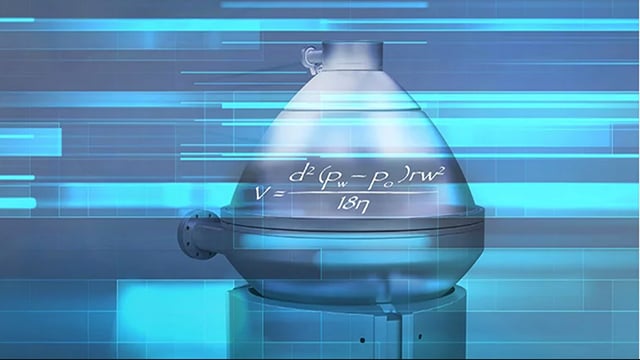

The PX centrifugal oil separator is built around a semi-hermetic, bottom-fed bowl design that gently accelerates feedstock to full bowl speed. Its low inlet pressure minimizes energy demand and simplifies operation. Unlike a basic oil separator machine, the PX series is engineered to handle viscous gums and soaps with ease. Thanks to Centrizoom, the separation interface can be adjusted during operation, ensuring continuous, high-efficiency separation. A low-noise design also supports better working conditions.

How do Alfa Laval PX centrifuges work?

The oil enters the centrifugal oil separator through a hollow spindle at the bottom of the bowl and flows directly into the disc stack. As the bowl rotates, the centrifugal force drives the heavy phase—including solids and sludge—towards the outer edge. Meanwhile, the light phase, consisting mainly of purified oil, moves inward toward the center and is then pumped out for downstream processing. The heavy phase is directed over a top disc into a chamber, where an adjustable paring device discharges it from the vegetable oil centrifuge. Sludge collects in a dedicated sludge space and is automatically released at preset intervals. This is controlled by a hydraulic system that lowers the sliding bowl bottom, opening the sludge ports at the periphery. The sludge is collected in the machine frame and exits the centrifugal separator through a cyclone for disposal.

Find out more about Alfa Laval Erosion Liner

Why should you have it?

Protect your PX 100 and 115 separator from wear and leakage with Alfa Laval erosion liner. It covers the sliding bowl bottom, a vital part of the separator, and can be easily replaced. Unlike Hexavalent chromium plating, which is harmful and soon will be banned in Europe, our erosion liner is safe and eco-friendly. Enjoy a more reliable and sustainable separation with our innovation.

How does it work?

If you want to extend the life of your centrifuge and avoid costly repairs, you need to meet Alfa Laval Erosion Liner. It is a protective liner that covers the sliding bowl bottom, which is a vital part of the centrifuge that regulates the separation and discharge of solids from the process. The Erosion Liner is easy to install and replace when needed.

How can you order it?

Ordering our erosion liner upgrade is simple. You will get an upgrade kit with all the parts and the liner, along with a manual on how to install it. To upgrade your existing separator, you will need to modify the sliding bowl bottom slightly. Just contact Alfa Laval and our workshops will take care of it.

PX range - vegetable oil separators and industrial centrifuges for fats and edible oil processing

PX 115 vegetable oil separator

- Gear drive

- Up to 1500 tons per day

PX 115e vegetable oil separator

- Direct drive – 5% power reduction compared to the traditional centrifuge

- Up to 1500 tons per day

Service

Extending the performance of your equipment

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.

Test, validate, and scale up your next separation solution

Whether upgrading your production line or running a proof of concept, Alfa Laval helps you choose the right separator solution with confidence. Simply get in touch to arrange a consultation and trial at one of our test centres, or to rent a unit for onsite testing.