CultureOne

Alfa Laval CultureOne™ is a premium range of disc stack separators designed for single-use bioprocessing. With proven innovations for gentle product handling and enhanced yield in cell harvesting, CultureOne™ delivers unmatched separation efficiency for high-density cell cultures.

Experience the benefits of CultureOne™ for improved cell harvesting in single-use bioprocessing

- Proven product recovery yields of up to 99%

- Easily scalable to larger Alfa Laval stainless steel separators

- 50 to 80% less water, energy, and cleaning agents compared to filter-based harvesting methods – with only a fraction of plastics

- Faster harvesting at large volumes and high cell densities

- Compact design and fast batch changeover

With superior separation performance, CultureOne™ centrifuges provide a clear centrate with minimal remaining solids content, significantly reducing the need for secondary filtration and lowering the ecological footprint.

Designed for ease of use, CultureOne™ separators for single-use bioprocessing can operate as stand-alone units or as part of a centralized system. Their advanced automation and connectivity ensure complete data integrity, fully compliant with 21 CFR Part 11.

Innovative features of CultureOne™ single-use technology in biopharmaceutical manufacturing

Hermetic Design™

The Hermetic Design™ of the CultureOne™ separator ensures gentle treatment, reducing cell lysis and avoiding foaming—making downstream purification more effective and reliable for biopharmaceutical processing.

TopStream™

Alfa Laval TopStream™ allows for the continuous removal of concentrated solids during separation, delivering a dense and intact solids stream that can be used for further processing or as a valuable by-product. This boosts separation capacity and enhances the efficiency of biopharma processing for high-density cellular materials.

UniDisc™

Alfa Laval UniDisc™ increases disc area for improved separation capacity by up to 30%, while at the same time providing an easy to clean design and never-before-seen degree of hygiene.

Safety and quality with Spinsert™

CultureOne's performance is based on the Spinsert, a patented single-use disposable bowl and disc stack assembly – fully sterilized and ready for processing. Easy to set up and replace, it ensures fast batch changeover. It is made from recyclable polymers suited for biopharma processing.

Main facts about CultureOne™

Improving yields at every scale

Improving yields at every scale

The CultureOne separation platform is designed to maximize the potential of every cell culture, delivering unparalleled yields, ensuring product quality with utmost security, and minimizing additional lysis. The range ensures consistent performance throughout the transition from R&D to full-scale production, allowing for seamless scalability.

Developed with the industry to meet the most challenging demands

Developed with the industry to meet the most challenging demands

The CultureOne separation system was developed in close collaboration with leading biopharmaceutical manufacturers. Its unique performance has been verified in a wide range of processes to ensure it can meet ever-changing demands.

Less waste in single-use processing

With CultureOne separators, you can reduce the amount of water, chemicals, and plastic consumables required for single-use biopharma processing by 50 to 80%. The result is lower costs and added sustainability.

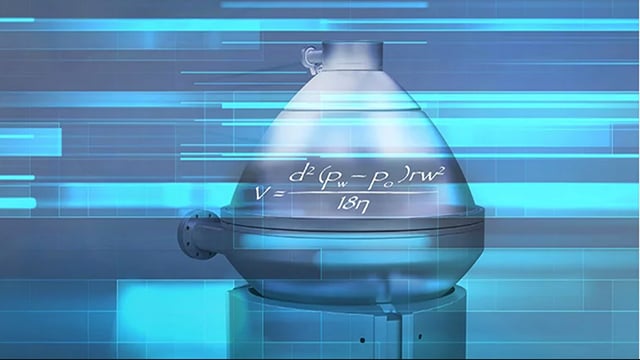

How this centrifuge enhances cell harvesting in biopharma?

Curious about the CultureOne™ separators? In this short animation, you can explore how these advanced systems support cell harvesting.

Proven and published performance in biopharmaceutical processing

BioProcess International published a study detailing the performance of CultureOne Primo. Made in collaboration with Genentech, the study shows that the single-use centrifuge gives a recovery yield rate of up to 99% in cell harvesting and single-use bioprocessing.

The CultureOne range

CultureOne™ separators enhance efficiency in single-use bioprocessing, increasing product recovery and streamlining workflows from R&D to production scale.

CultureOne Primo

- Processing capacity: 240 litres/hour

- Product recovery yield: Up to 99%

CultureOne Maxi

- Processing capacity: 720 litres/hour

- Product recovery yield: Up to 99%

* Capacity figures for fed-batch mammalian cell culture materials. Actual process performance is a function of individual material characteristics.

Your questions about CultureOne™ – Answered by our experts

What customers should expect from CultureOne range?

With Alfa Laval, you can easily transition from stainless-steel to single-use using the CultureOne range. Whether for pilot plants or GMP production, CultureOne offers versatile solutions for single-use cell harvesting.

How does CultureOne reduce its ecological footprint?

CultureOne minimizes filter use by 50-80%, addressing the challenges of increased batch sizes and cell densities. This scalable solution reduces waste, saves resources, and lowers costs while maintaining efficiency.

How does CultureOne meet current and future market demands?

The CultureOne system is compact, standalone, and easy to set up, making it ideal for experiments in diverse environments. It also supports collaborations with universities and innovation initiatives like GeneNova.

How does CultureOne ensure data integrity and connectivity?

Choose between standalone or centralized systems with open software for seamless integration with data historians or DCS platforms. CultureOne ensures full compliance with 21 CFR Part 11.

How does CultureOne reduce water, energy, and cleaning chemical use?

Unlike traditional systems, CultureOne separators eliminate the need for flushing and cleaning chemicals, cutting utility fluid use and waste by up to 80%. This makes it an eco-friendly and cost-effective choice.

What are the key advantages for biopharmaceutical customers?

CultureOne handles large batches and high cell densities, processing up to 200 million cells/mL and 700 liters/hour. It provides an adaptable, high-capacity solution, saving time and money as you scale your processes.

How does Alfa Laval support validation, qualification, and GMP production?

Alfa Laval simplifies validation and GMP production with expert support, standardized tests, and training. CultureOne ensures a smooth, reliable production process.

How does CultureOne deliver real scalability?

CultureOne ensures seamless scalability with consistent results across the Primo and Maxi models. It also integrates smoothly with stainless steel separators, providing reliable performance at any scale.

How does CultureOne meet GMP requirements?

The CultureOne range adheres to GMP standards, using familiar materials and rigorously tested designs to ensure safe and effective production of biotherapeutics.

How does CultureOne combine superior performance with a small footprint?

Compact and efficient, CultureOne fits into any manufacturing environment while delivering exceptional separation performance. The Primo and Maxi models offer high efficiency without compromising space.

Are you considering single-use technology for biopharmaceutical manufacturing?

Why switch to single-use processing?

A single-use separation system secures patient safety by eliminating the risk of cross-contamination between batches. Single-use processing also enables a reduced footprint and increased flexibility, with no need for sterilization: empowering manufacturers to bring new treatments to market faster than ever before.

A better harvest with centrifugal separation

Many single-use harvesting systems cannot efficiently separate high-density cell cultures. The resulting product loss dramatically impacts the productivity and profitability of biopharmaceutical operations. CultureOne overcomes this problem by combining high-efficiency centrifugal separation with secure and convenient single-use processing.

Services

Extending the performance of your equipment

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.

Test, validate, and scale up your next separation solution

Whether upgrading your production line or running a proof of concept, Alfa Laval helps you choose the right separator solution with confidence. Simply get in touch to arrange a consultation and trial at one of our test centres, or to rent a unit for onsite testing.