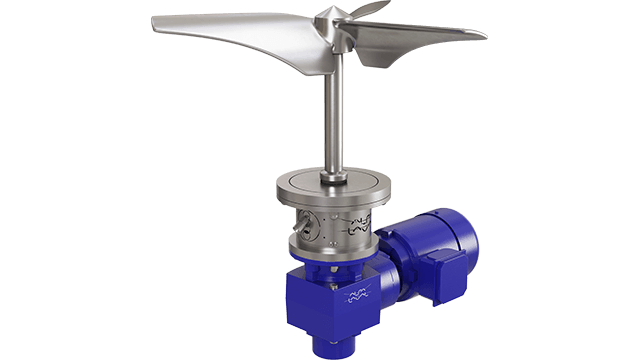

Hybrid Powder Mixer

The Alfa Laval Hybrid Powder Mixer is a dual-stage induction and dispersion system that quickly and efficiently disperses and mixes powders into a liquid stream. Versatile, cost-effective and easy to use, this inline, high-shear mixer produces homogeneous products at high yields and with minimum power consumption. The mixer is highly suitable for industrial applications, where process hygiene is critical.

Versatile hybrid powder mixer for various powder-liquid blending duties

- Low installation costs using a single, highly efficient unit for mixing and Cleaning-in-Place (CIP)

- Easily handles various powder particle sizes and liquid viscosities to achieve consistent, quality formulations

- Shorter processing time and higher yields due to fast, efficient mixing of high dry matter concentrations

- Reduced maintenance costs due to low spare parts inventory and service requirements

Ensure quality mixtures and reduce processing times with the Alfa Laval Hybrid Powder Mixer. The integrated process design boosts yield and promotes sustainable use of resources. Unmatched reliability and mixing efficiency make it suitable for powder induction, mixing and dissolution in industries that place high demands on hygiene and ease of cleaning, including food, dairy, beverage, biotech and home and personal care.

This inline high-shear mixer ensures gentle product handling, high dynamic shear, and complete powder dissolution. It simultaneously pumps the process mixture onward and speeds batch turnover through effective Cleaning-in-Place.

In combination with an Alfa Laval Rotary Jet Mixer, the Hybrid Powder Mixer is a critical component of a highly efficient cleaning-in-place (CIP) system. The powder mixer is available as a stationary or as a mobile unit.

How does the Hybrid powder mixer work

The two-stage Hybrid Powder liquid Mixer is generally integrated into a circulation loop connected to a batch tank. After adding liquid ingredients to the tank, the Hybrid Powder Mixer circulates the liquid over the tank. If fast dispersion into liquid is required and tank volumes are larger than 1 - 2 m³, Alfa Laval recommends using an Alfa Laval Rotary Jet Mixer.

When adding the powder to the liquid, the powder is added via a funnel. When the C-ball valve under the funnel is opened, the injector positioned under the valve creates vacuum in the funnel outlet, drawing the powder into the rotor-stator mixer and pre-blends the products. The rotor/stator (single rings) creates the main shear, dynamically and efficiently blending powder and liquid into a homogeneous mixture.

The pump impeller in the second stage creates the final shear and transfers the powder-liquid mixture into the tank under high pressure. Additionally, a portion of the powder-liquid mixture is sent via the injector bypass back into the mixer unit. The liquid flows from the injector aid in the venturi effect created at the funnel outlet, which enables the suction of powder into the liquid.

When mixing is completed, the Hybrid Powder Mixer may be used as a discharge pump or as a Cleaning-in-Place (CIP) recirculation pump to clean the tank when used in combination with an Alfa Laval Rotary Jet Mixer.

Happy Customers

The mixing equipment – Alfa Laval Hybrid Powder Mixer and and Rotary Jet Mixer – is key to getting the proper number of SKUs and the formulations. Automation enables us to eliminate human error, which ensures safety and a very high quality level of the final product.’

Shekhar Patel, US Hydrations

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Service

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Learn more about our service offer Troubleshooting

Serial number search Certification

Please contact us with any queries or questions.

Flow diagram for beverage syrup room

Visit the Application & Innovation Centre

Do you want to identify the optimal equipment for the job and discover tangible savings before deciding on upgrades? In the Alfa Laval Application & Innovation Centre, you can do just that.

Optimize™ by Alfa Laval

Optimize™ by Alfa Laval boosts your existing processes and enables up to 90% savings on water, energy and chemicals with only small and no-risk investments.

Explore the full Hybrid Powder Mixer range

Browse our product catalogue to select the right hybrid powder mixer for your application. You’ll be able to view technical specifications, compare options, find a local partner, and then request a quote - all in one place.

You might also be interested in…

Grow your business. Optimize your fluid handling systems – sustainably

Make your processes more efficient and more sustainable while achieving regulatory compliance and ensuring your business thrives. With Sustainable Optimization from Alfa Laval, you can save up to 80% in energy savings as well as 90% in water savings and cleaning media, while minimizing waste. Good for people. Good for planet. Good for profitability.

Services for Hygienic Tank Equipment

Get more out of your hygienic processing lines. Keep your Alfa Laval tank cleaning machines in top operating condition through services that extend the lifetime of your static spray balls, rotary spray heads and rotary jet heads. Let our global service network and local service experts optimize performance and provide you with total peace of mind.

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Animations

Visit the animations site and take a look inside a product to see and understand how it works.