Brew 80 gives a giant nitro boost to innovative British beer-makers

A UK brewery that began a decade ago with humble pilot-scale production and cuckoo-brewing roots (a model where brewers use another brewery’s facilities instead of owning their own) is now flying high after cracking the challenge of producing nitrogen-injected stout, thanks to an innovative solution delivered with Alfa Laval expertise and equipment.

DATE 2025-10-29

Bristol brewery Left Handed Giant was founded in 2014, when brewing enthusiast Richard Poole teamed up with bar owners Bruce Gray and Jack Granger to create the kind of “modern and progressive” beers they themselves loved.

The project started small, with a 200-litre kit. But as demand grew, the team turned to Cuckoo-brewing, using the facilities of larger breweries across the southwest to reach more drinkers without losing momentum.

In 2017, they moved into their own premises. Today, LHG brewery operates over two sites, a production only site as well as a brewpub. The production only site produces around 5,000 hectolitres of beer a year. Their beers are sold through independent pubs, bars, and bottle shops, as well as their own three venues.

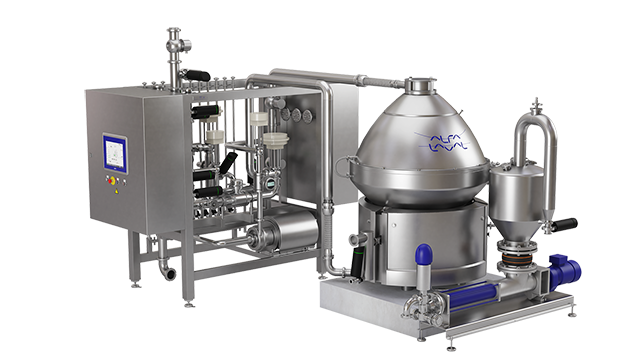

For the past two years, Alfa Laval has played a key role in this growth. Its Brew 80 system with ProCarb – Inline Carbonator has been a gamechanger for the brewery, especially in making its new nitro stout.

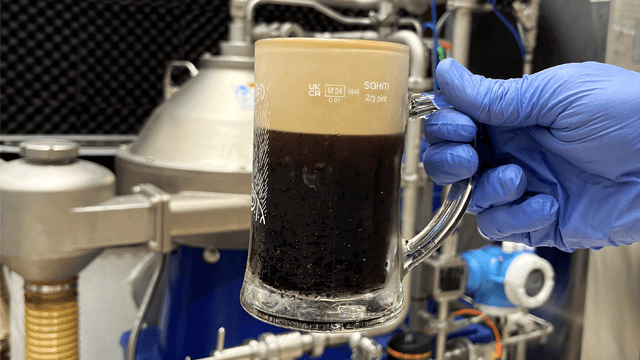

“The stout we were making before we had the procarb unit was a good stout, but once we were able to inject nitrogen, it became a great nitro stout and part of our core range. Nitrogenation is basically dissolving as much nitrogen into the beer as you can to give it a creamy head and a smooth feel on the tongue,” says Poole. “However, dissolving nitrogen into beer isn’t easy. It resists staying in solution, and the equipment needed is expensive.”

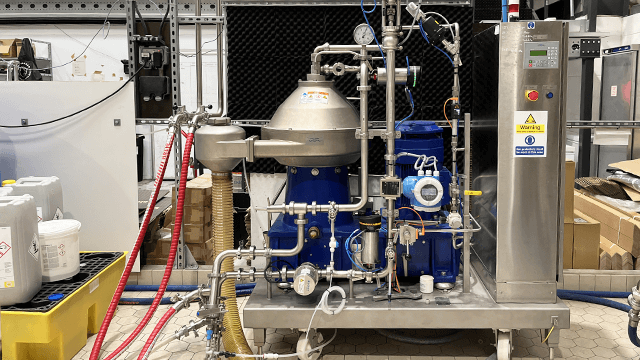

That led the team to test whether the Brew 80 could be adapted, using the ProCarb feature to dissolve nitrogen instead of carbon dioxide during centrifugation, before storing and packaging the beer from nitrogen-filled bright tank.

“It wasn’t something Alfa Laval had seen done before, but they worked with us to test it, and we’ve been delighted with the results,” Richard says. “Basically, we could not make our new nitro stout without this bit of kit and for us it has been a very convenient and easy solution.”

The stout now accounts for about 6% of Left Handed Giant’s total output and has become a popular winter favourite. Its success is a victory for innovative and flexible deployment of equipment that was originally brought in to improve overall quality and the scheduling of the hazy ales and IPAs brewed on the site.

This challenge was also efficiently tackled, as the improvement in scheduling achieved has meant that the team has been able to shorten timescales, with Richard estimating that they have knocked a week off the production time for every beer – and ten days off some. That means they can introduce a third more brews in a year.

“We were getting variations in clarity with the presence of yeast and hop particulates during the packaging of the beer, and this was impacting on scheduling and quality, so that’s when we started looking at a centrifuge solution,” explains Richard.

“We had talked to other brewers and they had good things to say about Alfa Laval’s Brew 20s, and Brew 80s. After some thought, we decided to go for the larger Brew 80, which we had had our eyes on for a few years. I’m delighted that we did because it means we can now get that stability and consistency in the brew with bigger batches really quickly and efficiently.”

Now used on all site-brewed beers, the Brew 80 practically eliminates all yeast particles, preventing sediment, over-carbonation, and continued fermentation. The result is improved quality and longer shelf-life.

The system also brings certainty to scheduling. “The certainty has been a godsend,” says Poole. “Previously we might choose a packing day and the day before we would check the clarity of the brew and realise we couldn’t do it. Now we can be certain that we will be able to package on the day, or the day after centrifuging.”

Yield improvements have increased a couple of percent, but stability and reliability have been the real gain. Since its installation in 2023, the Brew 80 has only required two scheduled annual services and minor repairs.

“I’m amazed at how effective and problem-free it has been, given the complexity of the equipment,” says Richard. “I’m cautious by nature, but it’s very impressive. With good processes, it delivers day after day. If there’s an issue, we get next-day service or immediate phone support from Alfa Laval.”

“We’re delighted. It is a good bit of kit which has obviously been fine-tuned over the years through use with other breweries and we are reaping the benefits of that now.”