Brewing with purpose

On Scotland’s Black Isle Peninsula – where the sea air sweeps across fields of organic barley grasses reaching for the Highland sun, Black Isle Brewery produces more than just beer. It brews purpose. As a Certified B Corp and pioneer of regenerative farming, Black Isle has crafted 100% organic beer since 1998, driven by a deep commitment to biodiversity, community and uncompromising flavour. So, when the team set out to create a low-alcohol beer worthy of the Black Isle name, shortcuts weren’t an option.

DATE 2025-11-07

Introducing non-alcoholic artisanal beer

The vision: expand the range with low-alcohol brews that still taste like Black Isle. The challenge: honour the brewery’s values, make the best use of limited space, and preserve the beer’s character.

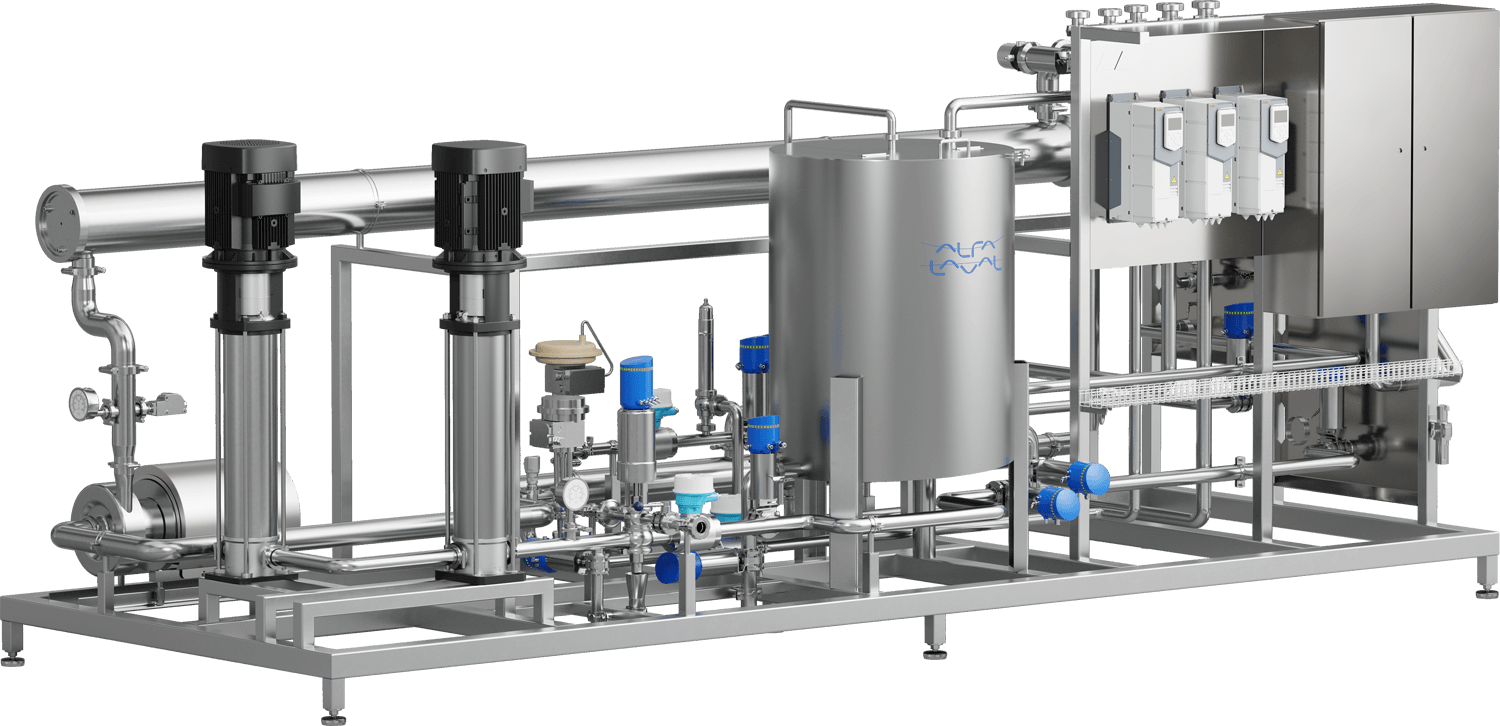

That’s where Alfa Laval’s Low-alc de-alcoholization module came in. Compact and efficient, the reverse osmosis-based solution is purpose-built for craft brewers – removing alcohol to low levels while protecting what matters most: flavour, aroma, colour and mouthfeel.

“Aroma retention was critical,” Mellen explains. “We’d tried samples from other systems, but most fell flat. The Low-alc delivered what we had been searching for – a low-alc beer that tastes like beer.”

Black Isle now proudly pours three low-alcohol beer styles: a citrus-forward IPA, a crisp lager, and a dark-roasted oat stout. Each is true to the brewery’s bold signature styles and made with the same organic hops and barley as their full‑strength counterparts.

Smart brewing, simplified

Fully automated and easy to operate, the Alfa Laval Low‑alc module streamlines the de-alcoholization process:

- Upconcentration – The beer circulates through Alfa Laval’s high-performance reverse osmosis membranes, which gently remove ethanol while preserving delicate flavour molecules.

- Diafiltration – Deaerated water from the Alfa Laval Aldox Mini is added to remove more ethanol and increase yield without compromising the taste.

- Final refilling – The beer reaches its target ABV, efficiently completing the filtration process without disruption.

“It’s clean, it’s consistent, and it’s hands-off,” says Mellen. “We save on labour, reduce lab testing, and minimize human error. That’s peace of mind in every batch.”

With flow rates of 40–60 hectolitres per hour and an automated control system, the Low-alc module gives craft brewers like Black Isle straightforward, premium-quality results – without the complexity.

We weren’t going to slap a label on a subpar beer and call it ‘low-alc.’ It had to be good. It had to be true to our values.

Richard Mellen, Head Brewer at Black Isle

Crafted for brewers who care

At the heart of the Low-alc module are Alfa Laval’s proprietary membranes, installed at 2,500+ breweries worldwide. Backed by 50+ years of expertise, the Alfa Laval spiral membrane filtration system delivers the quality that brewers demand.

By pairing the Alfa Laval Low-alc with the Aldox Mini water deaeration module, Black Isle gains a hygienic, plug-and-play solution with automated CIP, engineered for efficient, high-quality batch brewing.

Compact, versatile and future-ready

The Alfa Laval Low-alc module integrates seamlessly into Black Isle’s processing lines without requiring major changes or expansion. But don’t be fooled by its compact footprint, the Low-alc is built to do more:

From hard seltzer base clean-up and partial ethanol removal for low-alc variants to high-quality reverse osmosis water production, the same unit supports a growing portfolio.

“We’re eyeing hard seltzers next,” says Black Isle’s head brewer Mellen. “Using the same system makes it a no-brainer. With Low-alc, we’re shaping our future.”

Better beer, wider impact

Black Isle embraced low-alcohol beer to deliver the full flavour, aroma and mouthfeel of their full-strength brews to a growing community of beer lovers. Around the world, people are choosing great-tasting low-alc and no-alc beer – no matter their schedules, lifestyles, or reasons for cutting back on alcohol

The Low-alc module didn’t just fill a gap. It spoke to our purpose. It kept us true to who we are – brewers who believe premium organic beer should be enjoyed and do some good.

Richard Mellen, Head Brewer at Black Isle.

Highlighted Technologies

Low-alc de-alcoholization module

The Alfa Laval Low-alc uses cross-flow spiral membrane filtration to gently and at low temperature reduce alcohol content while preserving the natural flavour and character of beer and fermented beverages.