Alfa Laval technology transforms refinery performance with major production and maintenance boosts

The introduction of Alfa Laval technology at a major olive oil refinery in southern Spain has revolutionized the performance of the facility – significantly increasing production capacity and reducing maintenance costs.

DATE 2025-08-06

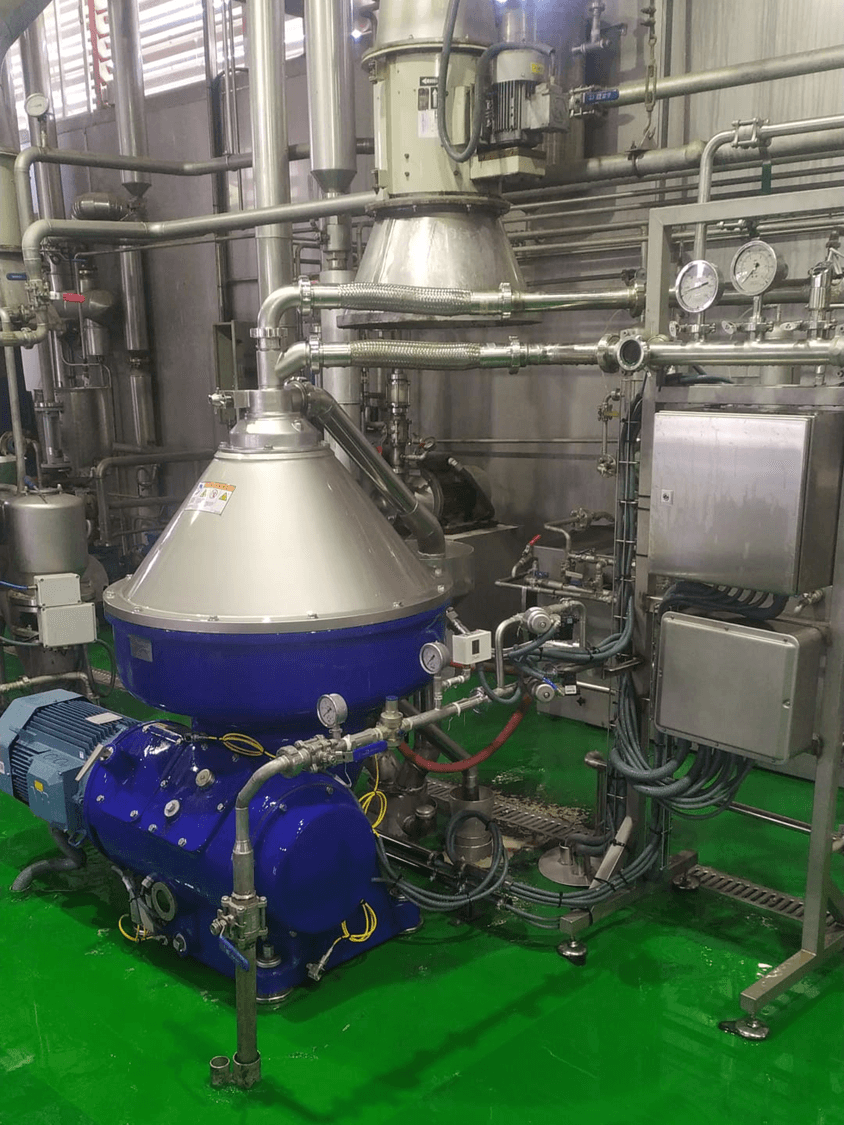

The transformation at the Qorteba oil refinery is down to the installation of Alfa Laval’s VO30 centrifuge unit with a liner. Managing 300 tonnes of product a day, the installation of the VO30 has eliminated unplanned stops at the plant. This improvement means an extra 1,200 tonnes of oil are refined every year.

The results have delighted the team at the refinery, which is part of the DCOOP Group and is based in the town of Alcolea, near the city of Cordoba. They had become increasingly frustrated with an outdated non-Alfa Laval centrifuge, which was used for the washing phase before the bleaching step.

The ageing centrifuge was struggling to cope, with clogging in the bowl, and severe wear on critical elements, such as the sliding bowl bottom, causing vibrations and badly affecting performance, with more downtime and escalating costs significantly impacting profitability.

A suitable moment, then, for Alfa Laval colleagues Belen Villalba and Favian Guevara to visit the facility, listen to the challenges the customer was facing, and promote the benefits of the VO30 centrifuge unit with Alfa Laval Erosion Liner, which reduced their repair costs by 94%.

“They were very unhappy with their situation, and we were immediately speaking the same language,” says Belen, Business Developer for Oils & Fats at Alfa Laval Iberia. “Their challenges were perfectly matching the capabilities of the product we were promoting, and it quickly reached a stage where they agreed to replace one unit, opening the door to what has become an excellent working relationship.”

Favian, Regional Sales Manager for Edible Oil & Protein for the global Alfa Laval sales team based in Sweden, adds: “While we had not worked with Qorteba before, we do supply a number of DCOOP Group facilities, so they were aware of what Alfa Laval’s equipment could achieve.”

The Qorteba team were particularly concerned about the wear and tear of the bowl in their centrifuge and the hard-chroming surface treatment method used to repair the sliding bowl bottom from damage, which was a hassle in terms of cost and downtime. Fortunately, Alfa Laval had the answer.

“The VO30 unit has a sliding bowl bottom with a liner that protects the bowl from erosion damage, and now they can simply change the liner on a regular service,” says Favian.

Since the installation of the Alfa Laval VO 30 unit in 2023, the Qorteba team could not be more delighted with the results, with plant manager José Carlos Gómez declaring: “This has been unbeatable value for money, and this unit gives us peace of mind!”

Alfa Laval is now the preferred separation partner for the facility following the impressive success of the VO30 centrifuge.

A key benefit for the customer has been the robustness of the unit. The Alfa Laval Erosion Liner has resolved the previously severe erosion problems by protecting the sliding bowl bottom, while the VO30 offers a more flexible and robust discharge system, ensuring no solids are left in the bowl, eliminating the earlier issues of clogging and high vibration. The unit is also self-cleaning which further reduces downtime and delays.

On top of this outstanding operational performance, the customer was also impressed with the speedy delivery of the equipment and the ongoing service provision supplied by Alfa Laval, which includes ConditionAlert™. This technology monitors the mechanical status of the rotating parts of the separator 24 hours a day and flags any issues that may lead to an unplanned shutdown before they happen.

“Service is important for the customer, and they have been very happy with the support we offer,” says Belen. “We have responded quickly to any issues, which has built their trust in us. Alfa Laval ConditionAlert™ not only monitors the equipment, but also keeps people connected. This means that the people at the plant have an open link to Alfa Laval, which is important for both them and us.”

Related products

Tags

All