Unique Bactofuge ® technology for high-density fermentation harvesting delivers multi-million-dollar boost for pharma giant

Alfa Laval’s unique Bactofuge® technology, combined with its ground-breaking Hermetic Design™, demonstrates the capability to improve recovery performance and enhance the profitability of the pharmaceutical industry’s leading players.

DATE 2025-11-05As these major companies increasingly shift towards a high-density fermentation process when producing valuable therapeutic treatment, they face the downstream challenge of effectively separating and clarifying broth which has high solid content.

With traditional disc stack centrifuges and filters struggling to address these changed condition, leaving millions of dollars of valuable product behind in the waste materials, a long-time customer turned to Alfa Laval to develop a game-changing solution: the unique Bactofuge® technology.

For two years, Alfa Laval team worked together with the customer, and in 2022, the biopharma company replaced their already profitable Alfa Laval clarifier with a new Alfa Laval separator. Indeed, the numbers are striking - switching from a conventional clarifier to Alfa Laval’s separator with Bactofuge® delivered approximately a 6% increase in product yield, adding about $7 million in value per batch. The payback for the investment in the new equipment was achieved in less than a single batch.

Patrik Kagevi, Global Sales Manager for Life Science Technology, Biopharm & Industrial Fermentation at Alfa Laval, was part of the team that worked with the company on this challenge. He notes that the customer is delighted with the outcome and now has invested in a total of five centrifuges with Bactofuge® technology in order to realize similar improvements across multiple sites.

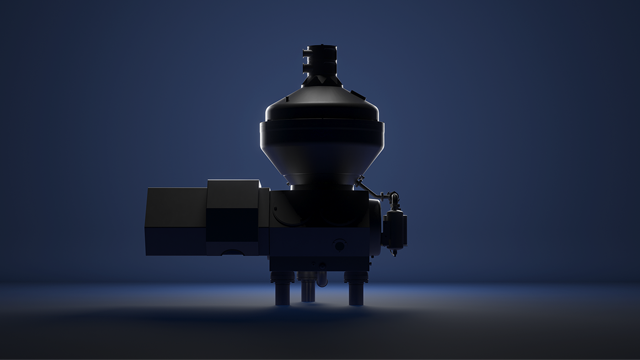

“When you have such an advanced and expensive product, the last thing you want to do is lose significant volumes in the clarification and separation process, but that is what was happening,” he says. “Filters were clogging, and the separation efficiency was being compromised, but we could see this was an ideal job for the MBPX 714 Bactofuge separator.

“There are key features in the Alfa Laval centrifuge which make it ideal. The Hermetic Design, for a start, means it has a whole rotating assembly that is fully liquid filled, which brings huge benefits.” The most significant advantage is that it introduces low shear forces at the centrifuge inlet, enabling much gentler handling of the sensitive cells compared to the treatment they received from the clarifier.

“The feed is not rotating when it comes in and has to be accelerated to several thousand rpm in a fraction of a second,” explains Patrik. “When you have something as delicate and fragile as cells that will break very easily, you have to make the acceleration to be very smooth with as low shear forces as possible. That is enabled with this fully liquid filled bowl.”

The consequences of not breaking the cells are two-fold: the process does not create a lot of small-cell fragments that are difficult or even impossible to separate so you get clearer liquid out, hosting the targeted molecules; and there is also no release of intercellular proteins mixed with the target protein, and that makes downstream purification easier.

The game-changing feature for high-density cell separation is the Bactofuge®. Its importance in this type of application is so significant that it is even reflected in the centrifuge’s name. Its outlet design enables continuous discharge, delivering higher throughput and yield while reducing downstream filtration needs and shortening processing time.

“Since it is a continuous process, you get a constant flow which means no variations in outcomes, which you would have with an intermittent model, where you get bursts of unseparated solids with otherwise clarified liquid,” says Kagevi.

When you take out separated cells in this continuous way, it is possible to optimize how concentrated it is. “Ideally you would want 100% concentration, but you have to let some liquid go with cells so that it flows,” says Kagevi. “By just tweaking the outlet, you can find the sweet spot of the liquid flowing, but with as high concentration of cells as possible, which is difficult to do with other types of technology.”

The customer is achieving results of over 90% concentration, which is very high, especially when compared with a previous figure of around 75%, which they were getting the conventional clarifier.

The way the Alfa Laval Bactofuge is designed also makes it possible to monitor and regulate the flows of separated biomass in one outlet and clarified liquid in the other outlet more precisely, and by use of flow meters and regulator valves, the customer can ensure they keep conditions constant.

“This is what we are proud to do at Alfa Laval,” says Patrik Kagevi. “This is a customer at the cutting edge of technology development, and we have created a solution that is keeping pace with the advances they are making.

“For them, it is now a no-brainer. They are integrating the Bactofuge into all high-density fermentations, gaining a strong advantage in the cost of production and improving the accessibility of these medicines.”