Visual Condition Assessments minimse downtime at Chivas’ whisky distilleries

The whisky industry is booming, and modern consumers are increasingly appreciating the consistent and smooth taste of single malt and blended Scotch whisky, such as that made by Chivas Brothers. Efficient production and minimal unplanned downtime are the keys to meeting this growing global demand. That’s why Chivas are utilizing Alfa Laval’s Visual Condition Assessments to avoid unnecessary production stops and breakdowns.

DATE 2025-04-23

Alfa Laval Visual Condition Assessments allow Chivas to plan heat exchanger maintenance

Chivas is one of the world’s most famous Scotch whisky brands, often marketed as a premium whisky for discerning drinkers. Its owner, the Pernod Ricard company currently has twelve distilleries in Scotland, and plans to expand production to meet growing demand in the future.

Shorter ‘silent seasons’

Like most whisky manufacturers, Chivas schedules production shut downs during the summer months – so-called ‘silent seasons’ – so its distilleries can perform essential maintenance on equipment. This is a crucial period in the whisky production cycle, ensuring smooth-running operations and the maintenance of high quality standards once production resumes. However, due to the increase in global demand, these silent seasons have been shortened to as little as ten days, putting pressure on distilleries to carry out their annual maintenance tasks in record time.

Auditing heat exchangers

One of the key tasks performed during a shutdown is the maintenance of heat exchangers on the production site. Traditionally, Chivas technicians would open certain selected heat exchangers to see if they needed cleaning or if the plates needed replacing. Technicians opened, checked and closed numerous heat exchangers which is time consuming, sometimes unnecessary and increases the risk of issues due to disturbing the pack. With little predictive analysis on the heat exchangers, Chivas had no way of planning for upcoming maintenance needs.

An efficient, hands-off solution

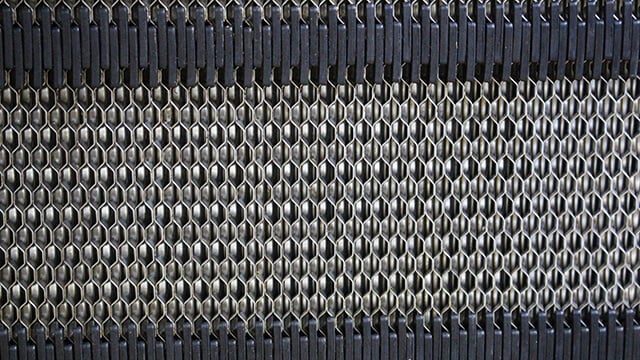

Chivas first invited Alfa Laval to talk about how they might improve this situation back in 2020. The whisky maker wanted to know if its heat exchanger maintenance process could be made more efficient; if there was any way for issues to be picked up in advance thereby enabling the creation of longer term maintenance plans. Alfa Laval proposed the use of Visual Condition Assessments (VCA) which would eliminate the need to disassemble and reassemble heat exchangers. Instead, an engineer could go to the site and inspect the customer’s heat exchangers using a thermal imaging camera attached to a smart phone or iPad. The equipment could be checked for corrosion, leaks, fouling, incorrect installations and more – all without the need for a physical intervention.

Thanks to VCA and Alfa Laval, we have seen the benefits of thermal imaging, data collection and reporting.

Maintenance Department, Chivas

Reports enable planning

A VCA works in the same way regardless of the number of heat exchangers involved, and the result is a report listing what needs to be done. Maintenance tasks are marked as either urgent or not urgent, allowing Chivas to prioritise and plan. A typical VCA report contains:

- Unit data, including any changes and adaptations

- Pictures and description of problem areas

- Thermal image of the customer’s unit, with an interpretation

- Summary of findings and recommendations

A rolling schedule

The first VCA audit of Chivas’s distilleries was carried out in the spring of 2021, and covered all twelve production sites. It allowed the whisky maker to change out packs that were highlighted before facing an unplanned stop. A second rounds of audits were carried out in May 2023 and a third will take place in 2025. The rolling schedule can simply be repeated every 2 years.

Saving time, money and effort

Using VCA saves Chivas time and wasted effort on the part of its maintenance team. The VCA’s provide the data to plan maintenance and aid efficiency. Engineers only do what needs doing – no more, no less – which frees up more time for them to spend on value-adding activities.

According to the Maintenance Department at Chivas, the use of VCA technology has provided valuable data and greatly aided maintenance planning . “Thanks to VCA and Alfa Laval, we have seen the benefits of thermal imaging, data collection and reporting.”

Highlighted technologies

Alfa Laval Visual Condition Assessment will give you a quick overview of the state of your gasketed plate heat exchangers. You will gain insights about the actual condition of your equipment its detailed mechanical condition, need of repair and remaining gasket lifetime prediction.