From trial to transformation in bioethanol with decanter centrifuge

Partnering up with a US customer to trial new equipment on a working bioethanol line opened the door to a dramatic reveal of the striking energy and cost savings that can be made by introducing innovative Alfa Laval decanter technology to processing operations.

DATE 2025-10-08

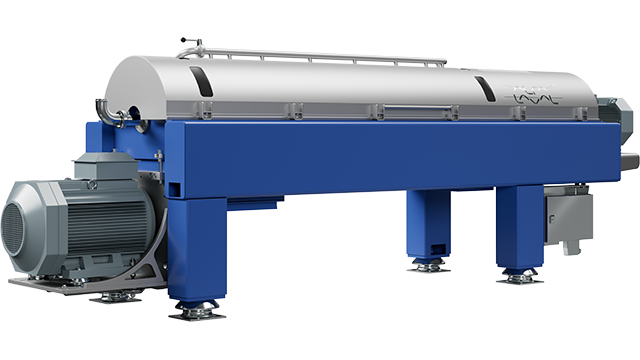

With bioethanol processors delivering a product high on volume but low on margin, anything that can be done in terms of efficiency can have a significant effect to their profitability. That was certainly the case when the Prodec 72 with VecFlowTM technology was introduced to the line at a US company processing corn stillage; a side stream when producing bioethanol.

Replacing one of several existing conventional decanters on the line, the Alfa Laval team were able to closely monitor the performance in a working environment and accurately estimate the benefits that this new technology could add to performance when compared with older equipment in terms of reduced power consumption, increased capacity, higher cake dryness and improved recovery.

“We wanted to replace an older unit for bioethanol production so we could see just how good the Prodec 72 was,” explains Rikard Krook of Business Unit Decanters. “These older machines were sturdy but not super-efficient and the Prodec 72 had been specifically designed for stillage dewatering with very low power consumption and high separation capacity, so during its development we were keen to test it on an actual production line.

“This is a large piece of equipment, though, so we contacted a number of big suppliers who had the sort of operations that could accommodate it. Our US customer who signed up already had existing machines so was the perfect match for us as we could make a direct comparison between the two types of decanter running side by side.”

That comparison gave a striking illustration of just how effective the Prodec 72 with VecFlowTM is, and gave plenty of fuel for Alfa Laval sales teams going out to sell the benefits of this advanced technology with hard statistics.

Mattias Nilsson of Business Unit Decanters says: “Dryers cost a lot of money and can often be the bottlenecks for investments, so if you want to expand your production, having a decanter which produces a dryer cake can make a big difference, It means the dryer has to expend less energy and increases overall efficiency.”

The high torque DD gearbox and operator-friendly control system are instrumental in producing that dry cake. When the solid content in the stillage varies, the Prodec 72 automatically adjusts the differential speed to maintain a constant torque level and constant cake dryness.

Meanwhile, a standout feature of the Prodec 72 VecflowTM is its patented separate rotating feed zone, which means less turbulence due to gentle feed acceleration and thereby less energy loss. Power consumption is cut even further with a specially designed discharge, as patented PowerPlates direct the centrate to support the rotation of the bowl. This means a 40 to 50% reduction in energy consumption compared to a standard decanter centrifuge, while also increasing separation capacity.

The results from the US customer showed that the payback on installing four Prodec 72 decanters with VecFlowTM would be less than 18 months as they deliver a cake which is 2.5% dryer, resulting in annual energy consumption cuts to the tune of 2 million kwh, with a reduction in CO2 emissions of 6,800 tonnes.

Mattias says: ”These results with just one new machine were striking and we extrapolate the figures over four machines as that highlights the clear benefits that a US mid-size operation producing around 100 MGPY (m gallons per year) of biofuel would see.”

The customer who facilitated this vital testing was certainly impressed, purchasing this particular decanter, and adding one more to another facility to ensure they were getting a march on their competitors by being the first to benefit from Prodec 72 decanters with VecFlowTM.

Many more customers have followed and the number of Prodec 72 decanters already supplied to the industry have made energy savings of around 5,000kW, enough to power a small village, with impressive reductions in costs to match.

Highlighted technologies

VecFlow™ Technology

Boosting separation efficiency

The unique VecFlow™ feature in a Prodec decanter is its patented separate rotating feed zone, which minimizes turbulence during acceleration. This smoother flow not only protects delicate process conditions but also enhances separation efficiency. For customers, this translates into reduced total costs of ownership and more efficient downstream processing.

40 to 50% reduction in energy consumption compared to a standard decanter centrifuge, resulting in annual energy consumption cuts to the tune of 2 million kwh.

Less than 18 months as they deliver a cake which is 2.5% dryer.

A reduction in CO2 emissions of 6,800 tonnes.