Rooted in tradition, boosted by innovation: Catalonia’s olive renaissance

Tradition and quality run deep through the olive trees at Tarragona – from the roots to the fruits – but in order to ensure a bright future in the Catalonian province, oil producers there needed to add quantity to the mix, while not impacting on their premium product.

DATE 2025-10-22

That has led to a new partnership between Coselva, the co-operative of growers in the area around the municipality of La Selva Del Camp, and Alfa Laval, which represents a significant milestone in the rich history of oil production here, going back to Roman times.

The project started with the century-old cooperative Coselva making a long-term assessment of how they could best serve their members and meet the needs of a growing population over the next hundred years—an exercise that became the catalyst for building a new oil mill and processing line to boost capacity.

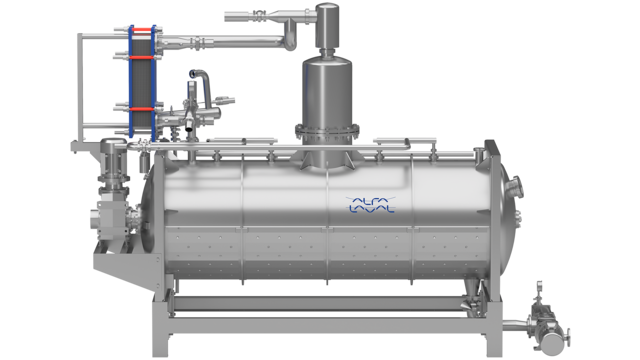

Investigations showed that Alfa Laval had the perfect solution, with its world-leading Olive Oil Booster, combining with olive crushers, Sigma decanter centrifuge, and Thermo Conditioning Module (TCM), to deliver increased yields while maintaining the premium quality on which this part of northern Spain prides itself.

For context, Spain is the olive oil capital of the world – yet Catalonia contributes only 5% of that, and this particular designation of origin area accounts for just 0.05%.

It prompted us to take a completely different approach,” explains Pere Ferre Masdeu, General Manager at Coselva. “That’s when we discovered this system from Alfa Laval that introduces something different in vacuum-based oil extraction. With this innovative oil extraction method, we achieved better paste depletion and, more importantly, significantly higher retention of polyphenols, antioxidants and aromas.”

These outcomes significantly boost the quantity and quality of the production, positioning Coselva to play a larger role in Spain’s olive oil industry, which in turn is playing a vital job in meeting the global food supply challenge. In fact, the Olive Oil Booster at Coselva has increased premium extra virgin olive oil extraction by 10% and improved polyphenol content by up to 20%.

The Alfa Laval Olive Oil Booster system replaces the conventional malaxer step for paste preparation in oil mills, and is actually a combination of different advanced technologies working together to maximize yield and quality. It combines thermal and separation technologies, utilizing a plate heat exchanger and a centrifugal decanter for a unique, stable solution in the market that doesn’t disrupt traditional process flow.

This mechanical method is capable of deaerating the olive paste while precisely controlling the temperature, resulting in key process and performance benefits. When integrated into an olive mill, it enhances decanter performance, and when combined with the olive crusher and high speed separator, it results in significantly higher olive oil extraction quantities and increased antioxidant components compared to traditional olive oil technology.

Alfa Laval Booster systems are available in a range of sizes, designed to run either in batches or, as at Coselva, continuously at an industrial scale, exactly like conventional malaxers.

Maximizing the yield and preserving the oil’s natural properties with a robust and flexible system is particularly important in these times of climate change, and this is where the TCM works wonders. Nuria Fonts is a plant manager at the facility and she explains:

Our harvests take place earlier each year. Thanks to the TCM system, we can adjust the paste temperature while adhering to cold extraction regulations. This allows us to produce premium oils even in challenging weather conditions.”

Antonio Benito, Sales Engineer at Alfa Laval Iberia, adds: “These innovative solutions are at the forefront of olive oil technology, they deliver maximum quality in the final product while streamlining production processes. Together with Coselva, we are setting new standards for the olive oil industry."

Indeed, the Coselva team has been so impressed with the results that they have decided to introduce Alfa Laval equipment into the second stage of the extraction process as well.

With this advanced technology now in place and working its magic, this quiet corner of Catalonia can make a bigger noise in the thriving Spanish olive oil industry – and having once produced oil that was taken back to Rome for the Emperor Hadrian, it is now home to a productive partnership with Alfa Laval that is set to build a whole new empire.

Highlighted Technologies

Coselva

Coselva was founded as a co-operative La Selva Del Camp on October 24, 1900, and began to produce olive oil for external markets in 1920.

It currently has 2,665 members, of which 1,250 are growers (producers) and 1,415 are collaborators.

Coselva looks to the future with the application of the most advanced technologies and prides itself in putting the quality of its products and the service to customers ahead of all else.

Its main activity is the production, transformation, and commercialization of the products obtained from the land of members and its strategy is based around three key areas: food quality and safety, social responsibility and respect for the environment.

In 2023, Coselva won the PITA Award in the Agroindustry category for its innovative vacuum milling system, which enhances both the quality and nutritional value of its 'Antara' olive oil.

Olive Oil Booster benefits

- Enhances oil quality by increasing phenol extraction. This means healthier, longer lasting oil with a higher retail value

- Maximizes oil yield throughout the entire harvest season thanks to innovative technology combined with efficient processes

- Improves sustainability with lower water consumption together with a higher process capacity

- Significantly increases the amount of ‘free oil’ released, which improves paste preparation and, in turn, decanter centrifuge performance

- Boosts oil mill profit margins through higher yields, higher oil quality and reduced impact on operational costs