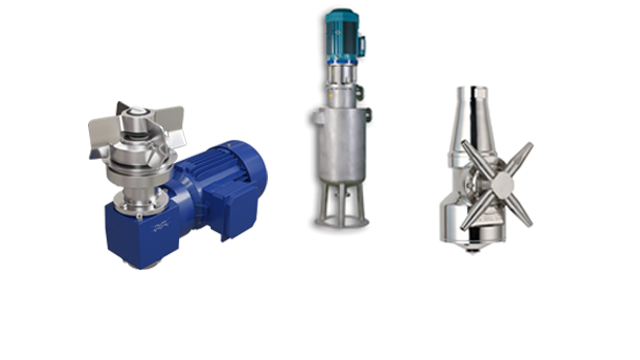

Tank mixers

Maximize uptime and yield with Alfa Laval tank mixers for hygienic and aseptic applications. Patented technology ensures efficient and uniform mixing of powders, liquids and gases while reducing the total cost of ownership. Compact, energy efficient and easy to maintain, these tank mixers enhance process flexibility, making quick, easy work of blending various product formulations with diverse viscosities, densities and volumes.

Tank mixing efficiency gentle mixing

- Maximize yields and minimize product loss

- Increase product quality due to minimal risk of contamination and optimal cleanability

- More uptime and greater process flexibility

- Quick, easy onsite maintenance

- Low energy consumption Focus on sustainability

Get unmatched process performance and higher yields from Alfa Laval tank mixers. Enjoy higher mixing efficiency, reduced energy consumption, and the highest standards of cleanability. These cost-effective tank mixers can disperse gas, powder, or liquid into a base liquid, mix down to the last drop, or handle double duty to clean the tank after mixing.

Let Alfa Laval tank mixers raise the standard of mixing efficiency to a new level across the dairy, food, beverage, brewery, and a broad range of applications that place demanding requirements on hygienic production.

How does tank mixers work?

Tank mixers such as magnetic mixers and rotary jet mixers have different operating principles.

Rotary jet mixer nozzles feed the liquid, gas, or powder into the base liquid in the tank. These jet mixers rotate around both horizontal and vertical axes in a 360° movement. This three-dimensional rotation enables fast, efficient tank mixing of the injected liquid, gas, or powder without requiring batch rotation. A circulation loop enables liquid to be pumped from the bottom of the tank and back into the industrial tank mixers. For faster mixing requirements, several rotary jet mixers can be installed in series as part of a larger process mixer system.

A magnetic mixer (also called a magnet mixer) has a radial impeller installed inside the tank. Due to the torque from a magnetic coupling, the impeller rotates, mixing the fluid inside the tank. The patented design of the levitating impeller enables dry running, maximizing yield by mixing down to the last drop. It also ensures full drainability of the process fluids and the free flow of Cleaning-in-Place media and steam throughout the mixer, ensuring thorough cleaning.

Happy Customers

International biotechnology company

Biotech firm achieves nearly 100% yield and thousands in recovered product.

Colorado Serum, USA

"Specifically, the Alfa Laval mixer has allowed us to generate a greater cell count, which equates to more doses and vaccines that we can sell. We consistently see a 30 to 50 percent increase in cell count"

Annie Ewing, microbiologist, Colorado Serum, USA

What can we do for you?

You can be our next happy customer. We are eager to help you!

Close at Hand catalogue

The hygienic equipment product catalogue "Close at hand" includes product leaflets, links to animations, brochures and lists for ordering purposes.

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Visit the Application & Innovation Centre

Do you want to identify the optimal equipment for the job and discover tangible savings before deciding on upgrades? In the Alfa Laval Application & Innovation Centre, you can do just that.

Optimize™ by Alfa Laval

Optimize™ by Alfa Laval boosts your existing processes and enables up to 90% savings on water, energy and chemicals with only small and no-risk investments.

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Animations

Visit the animations site and take a look inside a product to see and understand how it works.