MR

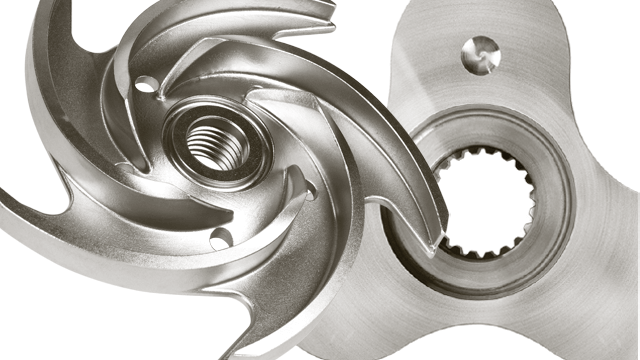

The Alfa Laval MR is a well proven liquid-ring pump specifically developed for effective pumping of liquids with entrained air. The construction of the MR makes it perfectly suited for use as a CIP return pump. Understanding the liquid ring pump working principle is key to appreciating its efficiency.

Specifically designed for pumping liquids that contain air or gas

- Ideal for CIP return applications: well-proven design suited to handle liquids with entrained air

- Easy to operate: excellent suction capability ensures limited impact on performance from changing fluid characteristics.

- Long service life: heavy-duty design used in CIP systems for decades.

The Alfa Laval MR pump is specifically designed for pumping liquids that contain air or gas and is most commonly used for CIP return applications across the food, dairy, beverage and pharmaceutical industries. The MR pump is available in three sizes to handle capacities up to 80 m3 /h and differential pressures up to 5 bar at 50Hz.

How the MR centrifugal pump works?

Understanding how liquid ring pumps work is key to understanding the efficiency of MR pumps. Like the Alfa Laval LKH and SolidC pump ranges, MR liquid ring vacuum pumps operate on centrifugal force. However, in the MR design, fluid is not directed into the peripheral wake or volute casing, but into channels on either side of the impeller, on the front and back plates of the pump.

This volume is then automatically reduced at the discharge port, creating pressure and forcing liquid out, thus providing the pumping action.

A proportion of the centrifuged liquid is retained around the periphery and re-circulates, forming a "liquid ring" that is used to maintain the prime.

The combination of expansion and contraction of volume, centrifugal force and liquid ring construction increases the permissible gas content in the fluid being pumped. This in turn makes this type of pump particularly suitable for fluids with entrained gases.

Close at Hand catalogue

The hygienic equipment product catalogue "Close at hand" includes product leaflets, links to animations, brochures and lists for ordering purposes.

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Service

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Learn more about our service offer Troubleshooting

Serial number search Certification

Please contact us with any queries or questions.

The MR has a unique construction which makes it perfectly suited to pump liquids with entrained gases. The MR is a well proven Alfa Laval technology that is highly suited to these applications.

The most common application for the MR is CIP return. This application contains is a mix of liquid and gas which needs to be pumped where standard pumps have difficulty.

Made from AISI 316L stainless steel and has a robust, heavy duty design which results in a long life.

Available in 3 models MR185S, 200S and 300. The range can pump up to 80 m3/Hr and pressure of up to 5.3 bar. The MR features an "External" mechanical seal for maximum hygiene and one seal can fit up to 3 models thus reducing spare parts holding.

Product benefits

- Unique construction suited to pump liquids with entrained gases

- CIP return application

- Pump up to 80 m3/Hr and pressure of up to 5.3 bar

Visit the Application & Innovation Centre

Do you want to identify the optimal equipment for the job and discover tangible savings before deciding on upgrades? In the Alfa Laval Application & Innovation Centre, you can do just that.

Optimize™ by Alfa Laval

Optimize™ by Alfa Laval boosts your existing processes and enables up to 90% savings on water, energy and chemicals with only small and no-risk investments.

Part of a broad pump range

Alfa Laval offers a comprehensive range of pumps intended for hygienic applications in the dairy, food, beverage, home care and personal care.

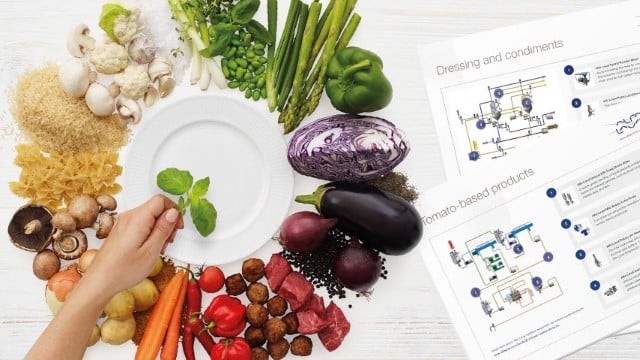

Food Logic

Alfa Laval's hygienic equipment combines high performance with gentle handling to preserve sensitive ingredients and keep up with the food industry trends. The equipment addresses four key challenges; supplying food products to consumers at a competitive price, getting the most from raw materials, reducing waste and emissions, and delivering safe and hygienic food products.

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Animations

Visit the animations site and take a look inside a product to see and understand how it works.