SolidC UltraPure

The Alfa Laval SolidC UltraPure centrifugal pump is part of a trusted range of high purity pumps designed for basic transport of fluids in high-purity applications where contamination safety is of paramount importance. With its hygienic design, cost-effective operation and quick, easy maintenance, the SolidC UltraPure offers excellent value for money.

Solid value for money – consistent performance, excellent hygiene and maximum cleanability

- Low contamination risk: full material traceability and USP Class VI elastomers to reduce the risk of process contamination from extractables.

- Cost-effective operation: consistent performance ensured.

- Quick and easy maintenance: wear parts changed in just a few minutes.

- Smooth qualification, validation and process control

Pump performance, hygienic design and ease of service are essential to hygienic processes. The Alfa Laval DuraCirc® Aseptic circumferential piston pump (CPP) delivers it all – high volumetric efficiency, EHEDG and 3-A conformance, and quick and easy service. DuraCirc® Aseptic is engineered for aseptic process applications in the dairy, food and beverage industries, primarily for packaging where extended shelf life is required.

For a cost-effective pump selection, the aseptic pumps come in five models, capable of flow rates up to 103 m3/h (453 gpm) and pressures up to 25 bar (363 psi).

Simplify service in terms of complexity and time with user-friendly features including a truly front-loading, self-setting single mechanical seal, use of a single long-life oil lubricant, and external shimming.

How does the Solid C UltraPure high purity pump work

SolidC UltraPure construction

The high purity pumps is ideal for biotech applications, and consist of a standard motor, stub shaft, mechanical compression coupling, stainless steel adaptor, back plate, impeller, pump casing and shaft seal.

Unique impeller design

Alfa Laval centrifugal pump features a unique semi-open impeller with a special vane design that ensures particularly low NPSHr (Net Positive Suction Head required), preventing cavitation and minimizing mechanical damage. This makes the pump perfect as a biotech pump in sensitive applications.

The impeller also features balancing holes for excellent circulation in the shaft seal area and reduced axial forces, minimizing wear on both the shaft seal and drive motor bearings. The semi-open impeller with balancing holes ensures high cleanability of the shaft seal, a key requirement for high purity pumps.

External shaft seal

The front-loaded external shaft seal, with the spring and washers mounted on the atmospheric side, is an important feature of the SolidC UltraPure biotech pump design. This configuration makes maintenance rapid, easy and inexpensive – it only takes about 5 minutes to replace the shaft seal.

Using a front-loaded shaft seal, combined with the pipe couplings mounted on the pump housing, also means there is no need to disconnect or remove the pump casing for inspection or maintenance. This saves time and money, and helps keep downtime to a bare minimum. This feature also means that a spare pump without casing could also be quickly put into place .

Alfa Laval uses the same shaft seal for the whole SolidC UltraPure biotech pump range – and the same seal is used in LKH UltraPure centrifugal pumps. This standardization keeps inventory down and makes replacing wearing parts a quick and easy task.

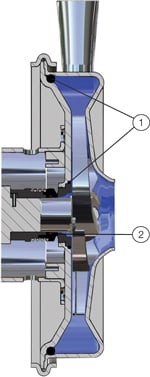

1: Defined O-ring groove providing firm positioning of the O-ring on pump casing and metal to metal contact provides a predefined compression of the O-rings with no crevices for contaminants.

2: External shaft seal with few wear parts and spring mounted on the atmospheric side, meaning no wear of the spring or other internal parts going into your product.

Warranty

Alfa Laval provides a 3-year warranty on all non-wearing parts, provided genuine parts are used.

Certification, specification and standards

The SolidC UltraPure range of high purity pumps has EHEDG certification. Learn more about SolidC UltraPure alfa laval centrifugal pump solutions in the product documentation.

Close at Hand catalogue

The hygienic equipment product catalogue "Close at hand" includes product leaflets, links to animations, brochures and lists for ordering purposes.

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Service

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Learn more about our service offer Troubleshooting

Serial number search Certification

Please contact us with any queries or questions.

Visit the Application & Innovation Centre

Do you want to identify the optimal equipment for the job and discover tangible savings before deciding on upgrades? In the Alfa Laval Application & Innovation Centre, you can do just that.

Optimize™ by Alfa Laval

Optimize™ by Alfa Laval boosts your existing processes and enables up to 90% savings on water, energy and chemicals with only small and no-risk investments.

360° Service and maintenance videos

You might also be interested in…

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Animations

Visit the animations site and take a look inside a product to see and understand how it works.