SB Pressure Exhaust Valve

The Alfa Laval SB Exhaust Pressure Control Valve is a pneumatic regulating valve that automatically releases pressure in a hygienic process tank when it exceeds the set pressure. To ensure safe pressure regulations at all times, the set pressure can easily be adjusted manually or from a remote location that is connected to the central control system.

Regulating valve that automatically reduces the working pressure

- Reliable control of tank top pressure

- Easy to integrate with SCANDI BREW® safety valves and top plates

- Fully cleanable with Cleaning-in-Place system

- Easy to integrate into existing installations

- Low investment due to simplified installation

This pneumatic regulating valve is designed for use in process tanks or vessels for hygienic applications in the brewery, food, dairy, beverage and many other industries.

How does the exhaust pressure control valve work?

Construction

The Alfa Laval SB Pressure Exhaust Valve consists of an AISI 316L stainless steel body, EPDM seals, and fittings for 4/6 mm nylon hoses for set point pressure and force opening. A cleaning nozzle and closing plug for the Cleaning-in-Place (CIP) inlet are also supplied. An optional pneumatic cleaning nozzle is available to replace the closing plug. The valve can be used as an integral part of SCANDI BREW® tank top system.

Operating principle

The exhaust pressure control valve is operated by means of the set point pressure being applied to the top of a membrane set. The pressure regulation will be identical to the set point pressure. The set point pressure is either reduced to the required pressure by means of a manual precision regulator or an IP converter controlled by a PLC.

When the tank pressure exceeds the set point pressure, the valve will open and release pressure through the valve side branch for atmospheric discharge or collection. To ensure correct working conditions, there should be no backpressure after the vent port.

After force-opening of valve by means of an air signal to the lower part of the membrane set, the valve can be effectively cleaned either by using the cleaning nozzle for inline cleaning of the valve at the same time as CIP of the vent/recovery mains takes place, or by using an optional CIP supply valve to connect a Cleaning-in-Place system to the valve housing.

Safe, effective pressure regulation

Easily integrated into a central process control system, this exhaust pressure control valve ensures safe, reliable and hygienic performance by releasing pressure in the process tank when it exceeds the set point pressure. To ensure safe pressure regulations at all times, the set point pressure can easily be adjusted manually or from a remote location that is connected to the central control system.

Hygienic, easy-to-clean design

To meet exceptionally high levels of hygiene, this regulating valve features simple, straightforward design. Smooth surfaces and food-grade finishes contribute to superior hygiene and cleanability. For fast, effective cleaning, a cleaning nozzle is supplied for inline cleaning of the valve at the same time as Cleaning-in-Place of the vent/recovery mains takes place. Alternatively, an optional CIP supply valve is available to connect a CIP system directly to the valve housing.

Flexible valve mounting

With flexible mounting positions, the valve can be positioned directly on tank top, as part of a tank top system or elsewhere along the pipework as long as there is proper drainage from the valve housing.

Option

- CIP supply valve

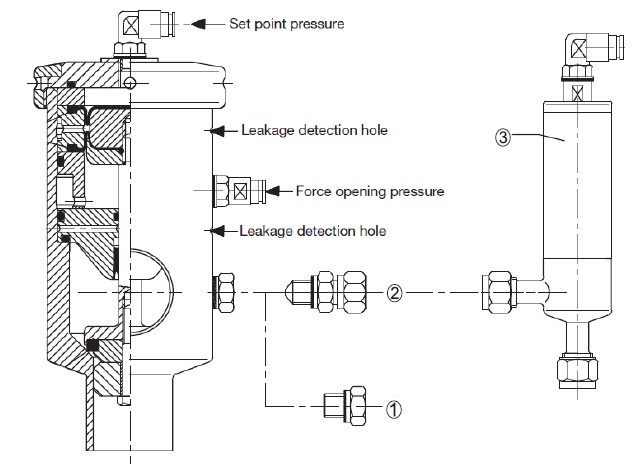

Pos. 1: Cleaning nozzle

Pos. 2: Closing plug

Pos. 3: Optional pneumatic CIP supply valve

Pos. 1 and 2 included with valve

Close at Hand catalogue

The hygienic equipment product catalogue "Close at hand" includes product leaflets, links to animations, brochures and lists for ordering purposes.

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Service

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Learn more about our service offer Troubleshooting

Serial number search Certification

Please contact us with any queries or questions.

Visit the Application & Innovation Centre

Do you want to identify the optimal equipment for the job and discover tangible savings before deciding on upgrades? In the Alfa Laval Application & Innovation Centre, you can do just that.

Optimize™ by Alfa Laval

Optimize™ by Alfa Laval boosts your existing processes and enables up to 90% savings on water, energy and chemicals with only small and no-risk investments.

Find the products you are looking for

The digital Alfa Laval Product Catalogue makes it easy to find and select the products you need. When you request a quote, the catalogue will list Alfa Laval’s partners in your region – and you can send your request directly.

You might also be interested in...

Ten top tips - Valves

Here are some tips and service videos to show how you keep your hygienic valves in tip top condition

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Animations

Visit the animations site and take a look inside a product to see and understand how it works.