SB Carlsberg Flask

Alfa Laval SB Carlsberg Flask has been developed specifically for aseptic yeast management in breweries. It is used for sterilizing wort and propagating pure yeast culture on a laboratory scale for use in yeast propagation plants in breweries (as well as in the dairy, food and beverage industries). The flask is made of materials that meet stringent sanitary requirements and can be easily autoclaved.

Ideal sterile environment for yeast cultivation

- Sterility assured by all-in one design solution

- Eliminates unwanted agents that can influence cultures thanks to hygienic, easy to clean configuration

- Safe and sterile transfer assured by integrated components and system approach

- Easy to move to location required

- Robust construction ensures yeast integrity

Alfa Laval SB Carlsberg Flask has a number of options to enhance the yeast management process. These include silicone hoses, other types of breathing and aeration filters and a two-wheel trolley for ease of transportation.

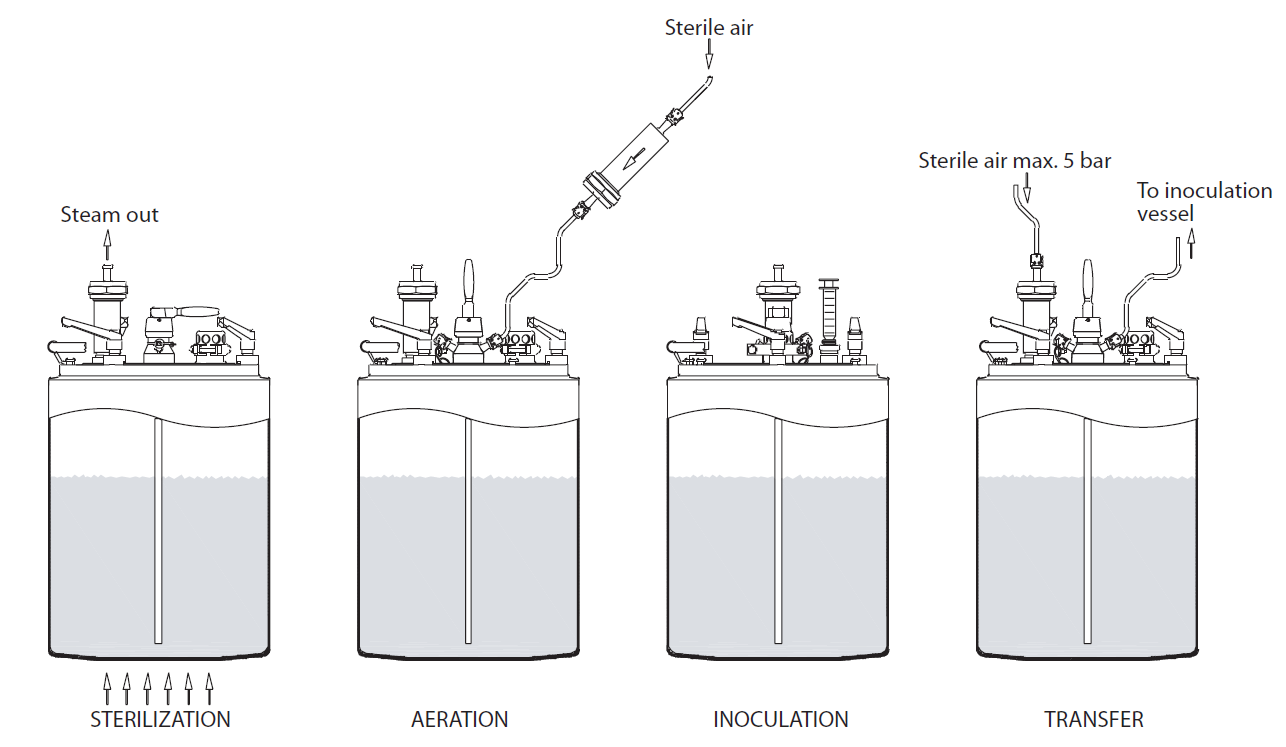

How does the Carlsberg flask work?

Yeast introduction methods

When the wort is well aerated, the yeast culture is introduced aseptically through the membrane fitting using a 150-200 ml syringe. You can also transfer dry yeast culture to the flask through the empty filter housing. If you need larger quantities of yeast, the lid can be dismantled and the culture poured into the flask. This procedure, however, requires a sterile environment and the highest degree of precaution.

Transfer to yeast propagation plant

The transfer of pure yeast culture into the yeast propagation plant should take place at the “high kräussend” stage under aseptic conditions and requires a sterile air supply to the breathing filter. Recommended sterile air supply during inoculation into yeast propagation plant is 2 bar and must not exceed 5 bar (72.5 psi) at any time. The yeast culture can be pressed from the flask into the inoculator once the membrane sample valve on the lid of the Carlsberg flask has been connected to a sample device on the receiving vessel (the inoculator).

Sterilization and connection procedures

The connecting hose, membrane sample valve and all other connections must be thoroughly sterilized with either alcohol or steam before transfer. Between operations, the valve can be sealed with alcohol, which can then be flushed out with sterile air prior to use.

Inoculation process

When you have made the connection and you are ready to inoculate, we recommend first opening the sterile air supply, then the membrane sample valve on top of the flask and finally the sample device on the inoculator.

When the culture has been transferred (indicated by a bubbling noise in the inoculator), we recommend continuing with the air supply for another couple of minutes to make sure that all of the yeast culture has been transferred.

Finally, the sample device on the receiving vessel and the membrane sample valve on the Carlsberg flask can be closed, effectively closing offer the air supply.

Cleaning and construction

After use, the flask needs to be taken apart and cleaned manually with normal detergents. The Alfa Laval SB Carlsberg Flask consists of a cylindrical container with a flat bottom and top cover equipped with breathing filters, a membrane sampling valve for aeration and product transfer, and a micro sample port for aseptic introduction of pure yeast cultivation. During the transfer of pure yeast culture from the Alfa Laval SB Carlsberg Flask to the yeast propagation plant, it is important that all hose tails are safely fastened with hose clips.

Preparation and sterilization

The flask is filled with wort to the net capacity (approximately 80% of the total volume) sterilized using an autoclave, a gas burner or an electric hotplate. The flask is then placed in a refrigerator or a cold room to cool the wort to the desired working temperature. The cold wort is aerated through the membrane sampling valve connected to the aeration lance, preparing the environment for yeast cultivation.

Yeast culture can be introduced aseptically through the membrane fitting with a syringe, or dry yeast culture can be transferred to the flask through the empty filter housing. These steps are essential for successful yeast cultivation.

The breathing filter can remain attached to the flask during sterilization. However, if the breathing filter has been sterilized separately, it is important to reattach it while steam is still evaporating from the flask (at the end phase of the wort sterilization) so that the filter connection is also sterilized. The empty filter housing can be used as funnel for transferring pure dry yeast culture to the flask.

Aeration and safety precautions

The cold wort is then aerated through the membrane sampling valve connected to the aeration lance. It is important to use sterile air. For safety reasons, it is also recommended to feed the wort through a filter mounted ahead of the membrane sampling valve .

Air supply and flow should be moderate to avoid foaming. It is important that foam does not come into contact with the breathing filter because it may block and damage the filter.

The easiest way to determine the right conditions for the air supply as well as the time needed for aeration (less than 10 minutes) is to test with the flask lid open. Note that you cannot use the yeast culture from these tests.

Close at Hand catalogue

The hygienic equipment product catalogue "Close at hand" includes product leaflets, links to animations, brochures and lists for ordering purposes.

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Service

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Learn more about our service offer Troubleshooting

Serial number search Certification

Please contact us with any queries or questions.

Visit the Application & Innovation Centre

Do you want to identify the optimal equipment for the job and discover tangible savings before deciding on upgrades? In the Alfa Laval Application & Innovation Centre, you can do just that.

Optimize™ by Alfa Laval

Optimize™ by Alfa Laval boosts your existing processes and enables up to 90% savings on water, energy and chemicals with only small and no-risk investments.

Find the products you are looking for

The digital Alfa Laval Product Catalogue makes it easy to find and select the products you need. When you request a quote, the catalogue will list Alfa Laval’s partners in your region – and you can send your request directly.

You might also be interested in...

Part of a broad valve range

Alfa Laval offers a comprehensive range of valves intended for hygienic applications in various industries including dairy, food, beverage,home care, personal care, biotechnology and pharmaceuticals:

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Animations

Visit the animations site and take a look inside a product to see and understand how it works.