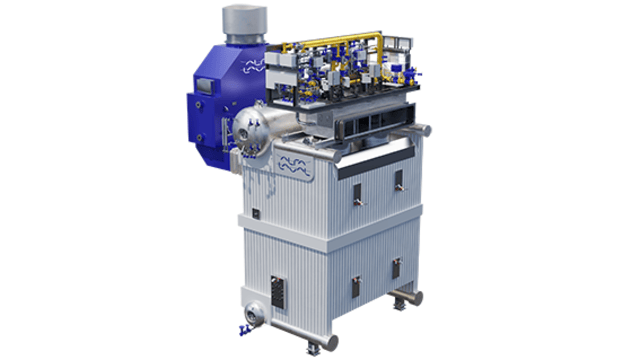

Aalborg D Multi Fuel

The Alfa Laval Aalborg D design employs “top-fired” burner technology, which provides optimal flame conditions that result in excellent combustion. The burner system can use both steam and air for fuel atomization and can be fired with multiple fuels (MDO/MGO, HFO, crude oil and fuel gases).

The Aalborg D design is compact, efficient and reliable

- High steam quality for power generation or process/utility steam

- Low operational cost, high efficiency, available also with an economizer for optimal thermal efficiency

- Reliable operation with more than 99 % uptime

- Available with emissions abatement technology, low-NOx FGR (flue gas re-circulation)

- Available for wide range of various fuels, gaseous and liquid, from standard marine fuels to various offshore crude qualities, including fuel co-fir

The Aalborg D design is based on a vertical “D”-shaped boiler configuration with steam and water drums interconnected via steam-generating tube banks. The furnace is made of membrane walls that form a fully water-cooled furnace. The convection section consists of straight pin tubes with bent pins, providing high heat transfer coefficient and low pressure loss.

In a steam boiler configuration, effective natural circulation is ensured at any operational condition through careful design of the pressure part. In a hot water heater configuration, effective circulation is ensured through careful design of the internal water passes and passages. In both cases, the results are excellent water circulation and heat transfer properties.

Documents

How it works

Features:

- Production of steam and/or hot water

- Steam boiler capacities up to 130 t/h

- Design pressure up to 40 bar(g)

- Superheating temperature up to approx. 400 °C

- Hot water heater capacities up to 90 MW

- Multi-fuel combustion technology (MDO, HFO, crude oil and various fuel gases)

- Integrated burner design that minimizes refractory

- Multi-burner design for larger capacities

- Available for indoor and outdoor, safe and hazardous area designs

- Full system scope auxiliaries optionally available, including various combustion skids, GVUs (open or enclosed design), feed water /hotwell/ deaerator tanks, and so forth

Service

We provide full support for our multi fuel boilers. Our support covers their entire life cycle, beginning with design, installation and commissioning and extending past warranty throughout the service life.

Alfa Laval Service Agreements will help the operators of the systems. A fixed-period Service Agreement makes operation planning and cost projections more secure. A well-crafted maintenance strategy offers transparent cost control and safeguards performance, lengthening your equipment’s lifespan and reducing your total operating costs. Preventive maintenance is the key to reliable performance. Our Preventive Maintenance Programme comprises annual and 30-month services that comply with regulatory inspection schedules.