AlfaCond

Alfa Laval AlfaCond condensers are specifically designed for condensing of vapour under vacuum. These plate surface condensers are ideal for use in applications such as vacuum condensers in evaporation systems, ethanol condensers in bioethanol plants, pan vapour condensers in sugar refineries, and as turbine condensers in small power plants. With its compact design, AlfaCond is easy to install where space is crucial.

Benefits of AlfaCond condencers

- Optional sub-cooling of condensate and non-condensable gases

- Flexible configuration

- Easy to install

- High serviceability

- Access to Alfa Laval’s global service network

Highly efficient and very compact

AlfaCond is the plate condenser designed for vacuum condensation, offering greater efficiency and a much smaller footprint than traditional shell-and-tube condensers. It is easy to clean using Cleaning-in-Place (CIP) or mechanical methods and can be configured with or without condensate subcooling.

Ideal when condensate recovery or limited space is a priority, AlfaCond removes non-condensables via the condensate outlet for optimal vacuum performance. Its glued gasket system ensures durability in all cleaning conditions, while features like pressure plate rollers, bearing boxes, and a five-point alignment system make maintenance fast and effortless, securing a long service life.

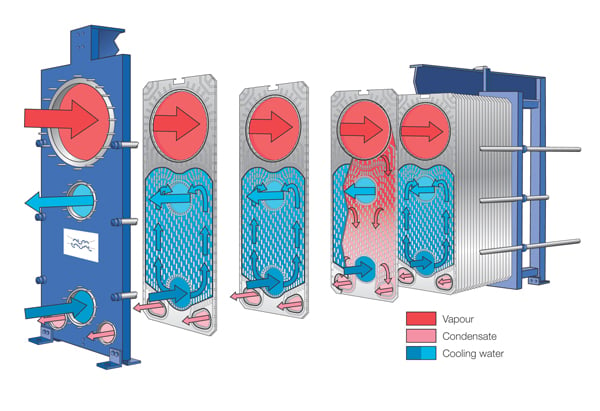

How the AlfaCond technology works

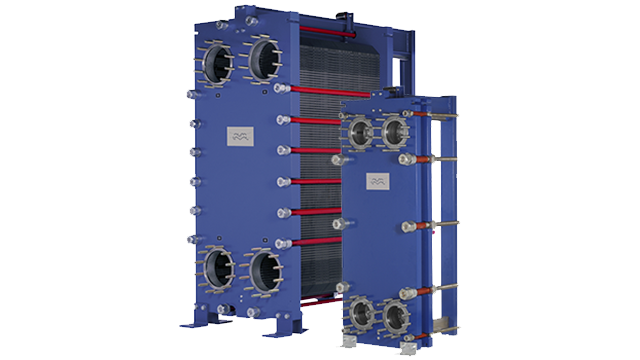

The heat transfer area of a gasketed plate-and-frame heat exchanger con sists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates on the AlfaCond alternates between laser welds and gaskets. It has a unique porthole configuration that is specifically designed for vacuum condensation. Vapour condenses in the welded channel and the cooling water passes through the gasketed channel.

The channel gap size is asymmetric with a larger gap on the vapour side and a smaller gap on the cooling water side. The result is a very low pressure drop on the vapour side and high velocity and turbulence on the cooling water side. Together, these maximize heat transfer efficiency and minimize fouling.

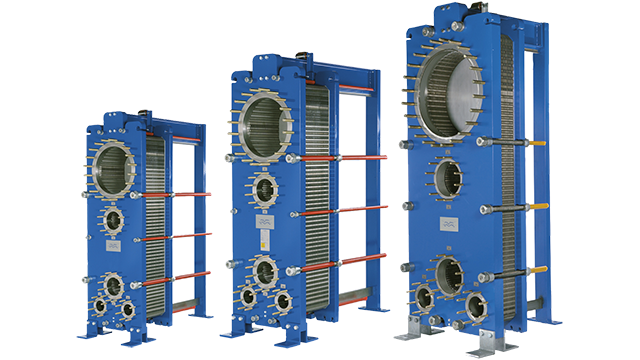

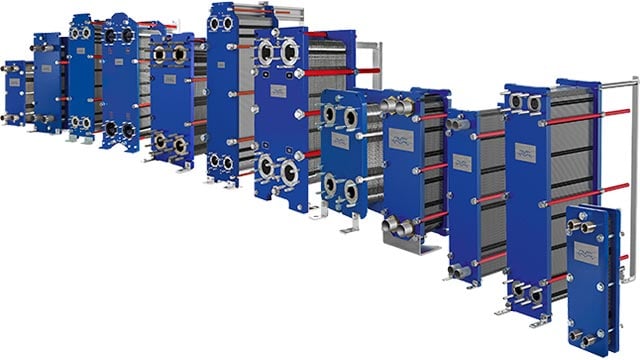

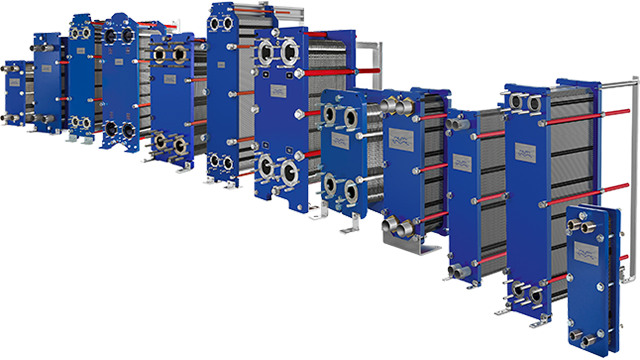

Part of a broad range of gasketed plate heat exchangers

Benefits of using Alfacond in the sugar process

Remaining profitable in the highly-competitive sugar market calls for sustainable solutions that reduce energy, water and maintenance costs while boosting yield.