Re-draft system

The Alfa Laval Re-draft system is a draft dispensing unit that rehydrates beer concentrate seconds before serving. Doing so enables breweries to realize significant cost savings from storing and transporting concentrates from the manufacturing facility to the point of consumption.

Boost sustainability credentials and reduce costs with beer concentrate on tap

- Up to 80% cost savings in packaging material and keg transport to and from the point of consumption

- Refrigeration and storage cost savings due to compact footprint

- Better bar station space utilization with easy-to-use draft dispensing

- Sell up to five times more beer and improve workplace safety since staff spends less time and effort changing kegs

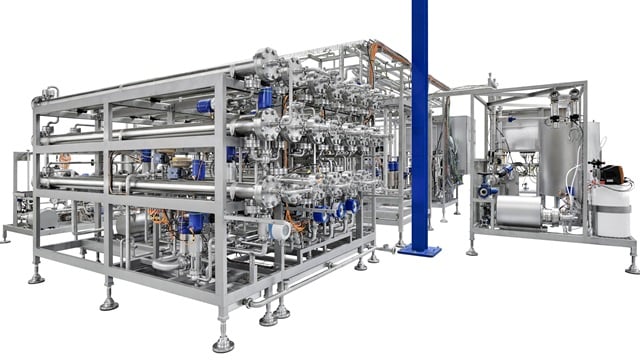

The Alfa Laval Re-draft is a compact, post-mix draft alcoholic and non-alcoholic beer dispensing system. It uses pure, carbonated water to rehydrate fully fermented beer concentrate, produced by the patented Alfa Laval Revos™ reverse osmosis technology, at the point of sale or regional packaging plants.

The resulting beer matches the exact flavour profile of the original product. Rehydrating closer to the point of consumption drastically reduces emissions and logistics costs through bulk transport.

The Re-draft system is part of the Alfa Laval portfolio for the brewery industry. It helps brewers and their customers meet sustainability targets by streamlining logistics and supply chains.

Key products

Alfa Laval Re-draft system

Preserves the traditional draft experience:

- Great-tasting, easy-to-dispense beer

- Same pouring experience (appearance/rate/tap)

- Potential for cleaning media savings and reduced cleaning frequency, depending on the concentrate

- Better space utilization at the bar station

- Self-cooling or integrated into a glycol system

Consistent ABV, CO2 and foam level in every pour

Same great taste, less volume

The Re-draft system supplies the same volume as traditionally packaged beer from a reduced-volume concentrate. Handling smaller volumes of concentrate increases workplace safety and reduces injuries. It also does away with the need to store kegs in refrigerated cold rooms onsite at the bar or venue.

How it works

Alfa Laval Re-draft system reconstitutes beer concentrate at the point of sale. It purifies and blends cold carbonated water with the concentrate, delivering a cold draft product on tap.

Service

Pilot testing and rentals of beer concentration systems

Test the Alfa Laval Revos concentration system and Re-draft system to determine whether these systems meet your requirements. Send up to 10 hl of your product to the Alfa Laval Revos Innovation Centre in Denmark for onsite testing and performance analysis. A Re-draft system is available for demonstration and testing to rehydrate the concentrate produced.

Alternatively, you can rent a Re-draft system and conduct trials reconstituting your beer concentrate at your facility or in a commercial setting.

Food system services

Alfa Laval Food system services help extend the performance of your food systems by maximizing the performance of your processes. This enables you to:

- Continually improve your operations to maintain competitive advantage

- Focus on uptime, optimization and availability

- Maximize return on investment throughout the life cycle of your food systems

Learn more about our service offer for food systems

Curbing carbon emissions - Learn more from our white paper

How can breweries and beverage manufacturing facilities reduce their carbon footprints while making operations more efficient? Reducing direct and indirect emissions plays an important role – from purchasing raw materials, electricity and manufacturing to packaging, materials and distribution. This white paper will focus on reverse osmosis (RO) membrane filtration for beer and beverage concentration as a cost-effective way for manufacturers to reduce the carbon footprint of their supply chains.

Q&As Revos concentration system

Find answers to the most frequently asked questions about the Revos beer concentration system here.