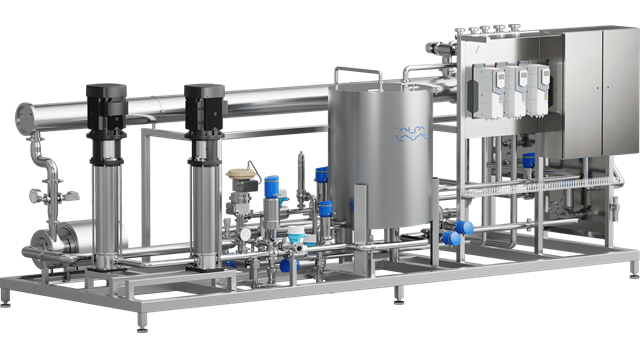

Beer de-alcoholization modules

Expand your share of the no- and low-alcohol market with Alfa Laval’s solutions for dealcoholized beer. Our cost-effective, plug-and-play modules gently remove alcohol while preserving flavour, aroma, and mouthfeel. Choose between the stripping or membrane filtration system—both ensure high yield, product safety, and easy integration. One system suits all beverage styles. Get to market faster and grow profitably with Alfa Laval.

Maximum flavour, zero compromises

- Outstanding taste

- Diversify your production with a single system

- Scalable flexibility

- Better for the planet and your bottom line

Choose between the stripping or membrane filtration system to find the perfect match for your dealcoholized beer production.

Integrating the De-alc module into our production lines not only helps Asahi meet its sustainability objectives but also strengthens our competitive edge.

– Mr. Jun Kubota, Global Chief Brewer at Asahi Group Holdings

Looking to produce de-alcoholized beer? Find the solution that fits your needs

How to remove alcohol from beer with our beer de-alcoholization systems

Alfa Laval offers two proven methods for beer de-alcoholization: stripping and membrane filtration.

- The stripping method for alcohol removal is ideal for high-volume, continuous production at 38°–40°C.

- The membrane filtration method is better suited for lower-volume batch production at 7°–15°C.

Both methods preserve the full flavour, aroma and mouthfeel of the original, full-strength beer, helping brewers and beverage manufacturers meet the rising demand for low- and no-alcohol alternatives without compromising on quality or flavour.

Removal of alcohol from beer using stripping

Stripping is a gentle, single-pass process that uses a soft process water vapour stream at 38°–40°C (<10 dH) in counter-current flow to remove ethanol from beer and fermented beverages. Operating at low temperature and pressure, it ensures highly efficient alcohol removal without the need for distillation, dilution, or product loss.

Key benefits

- Single-pass efficiency: achieves ABV targets without the need for recirculation

- Low-temperature process: preserves flavour and aroma by avoiding boiling

- Fast results: de-alcoholization occurs in less than a minute

- Energy-smart: optimal reuse of heat and process water

Learn more about the Alfa Laval De-alc dealcoholization module.

Removal of alcohol from beer using membrane filtration

This process uses high-performance reverse osmosis spiral membranes in a hygienic setup at low temperatures (7°–15°C or lower) to produce premium low- or non-alcoholic beer with flavour unaffected by heating. The membranes separate the feed beer or beverage into two streams:

- Permeate steam: water and alcohol, which pass through the membranes

- Retentate stream: concentrated proteins, flavour compounds, and colour, which do not pass through the membranes and are recirculated to the feed tank

This method is ideal for breweries and beverage producers who want to use a non-thermal, flavour-preserving solution that retains the sensory qualities of the original beverage.

Learn more about the Alfa Laval Low-alc de-alcoholization module.

You might also be interested in ...

Service

Food system services

Alfa Laval Food system services help extend the performance of your food systems by maximizing the performance of your processes. This enables you to:

- Continually improve your operations to maintain competitive advantage

- Focus on uptime, optimization and availability

- Maximize return on investment throughout the life cycle of your food systems

Learn more about our service offer for food systems