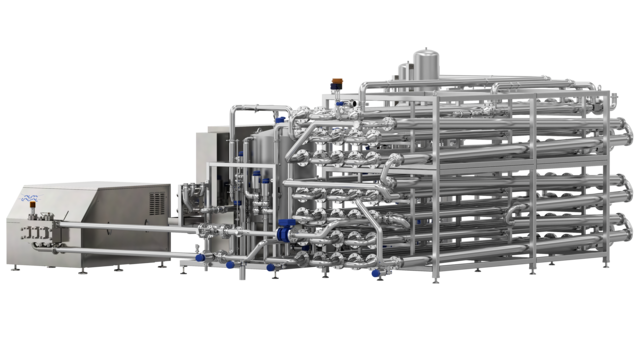

Steritherm VLM

Increase microbiological product stability by removing or inactivating microorganisms that cause product spoilage. The Alfa Laval Steritherm VLM is an aseptic multitube heat treatment system that sterilizes low- to medium viscosity products containing fibres and small particles. Based on a tubular heat exchanger, it ensures gentle product treatment and uniform heating and cooling. Versatile and robust, this aseptic sterilizer maximizes uptime and minimizes maintenance.

Secure process and product safety for low to medium viscosity food products through sterilization

- More uptime for fouling-prone applications, like high-fibre juices, compared to other technologies

- Reliable, low-cost operation with long run times and higher heat transfer efficiency than tube-in-tube designs

- Versatile handling of various capacities and product formulations

- High hygiene levels due to thorough cleaning-in-place

- Near maintenance-free operation due to no moving parts and low service requirements

Safeguard fresh food products from spoilage with the Alfa Laval Steritherm VLM.

The Alfa Laval Viscoline™ multitube tubular heat exchanger is at its core for effective sterilization. This multitube sterilizer treats products like milk, eggs, fruit and vegetable purees, fruit juices with pulp, ensuring food safety.

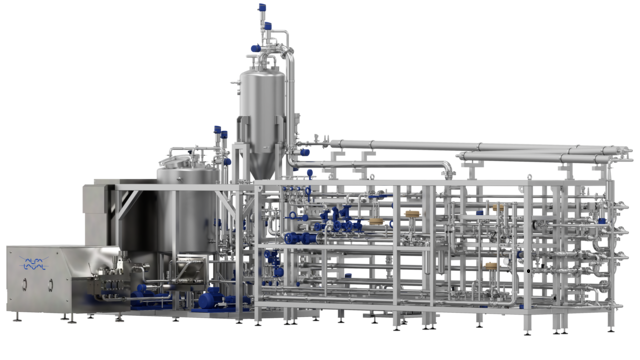

Pre-assembled and skid-mounted, the unit comes ready to install between an aseptic tank and filler. It ensures straightforward operation, safety throughout the packaging process, and next-to-no maintenance.

Choose models for:

- the removal of air from the product before treatment with integration of the Alfa Laval Alrox deaeration module

- direct and indirect heat recovery to improve energy efficiency

How does the Alfa Laval Steritherm VLM work?

Sterilization

Before sterilization of any product begins, the sterilization-in-place of the Steritherm VLM unit occurs, running superheated water at 125 °C (257°F) through the unit for 30 minutes.

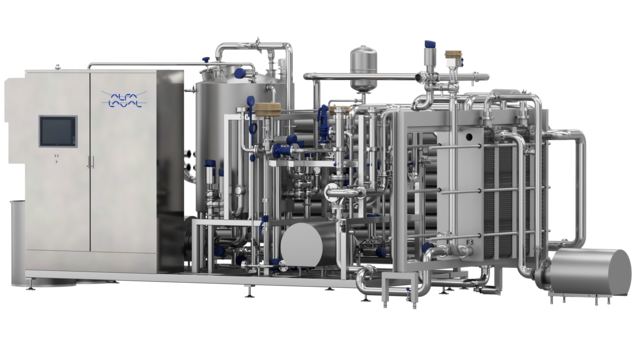

Balance tank

The product enters a balance tank, and an appropriate pump transfers the product to the heat exchange. A flow meter sends signals to the pump, ensuring constant feed into the heat exchangers. A temperature and a pressure transmitter monitor the product inlet temperature and pressure in the unit.

Heating by indirect regeneration

The cold product is preheated in a dedicated closed water loop, allowing indirect energy recovery that minimizes heating and cooling demand. The product is under overpressure compared to the media.

Final heating and holding

Final heating to the sterilization temperature is achieved through hot water recirculation. The hot water is produced in a dedicated hot water set by means of steam. The system is governed by a temperature transmitter which measures the product temperature at the outlet of the heat exchanger and subsequently controls the steam quantity with a modulating valve. The product is kept at the sterilization temperature in an insulated holding cell for the specified time.

Cooling

The product is cooled to the final filling temperature in three stages: first, by using the same closed water loop used on the preheating section (indirect energy recovery); next, by tower water; and finally, by chilled water or glycol solution in counter-current flow. A temperature transmitter and controls the flow rate of the final cooling media by sending signals to the modulating valve on the cooling media pipeline and measures the product outlet temperature.

Cleaning-in-Place (CIP)

Under normal running conditions, all surfaces in contact with the product are cleanable without dismantling the module. The necessary cleaning intervals depend on the products treated and the temperatures applied.

Control system

The module is automatic. Start and stop functions, set point and PID control parameters can be inspected and set. Relevant process data, for example, plant status, actual temperatures and flow rate, and alarm status, are displayed.