BTUX

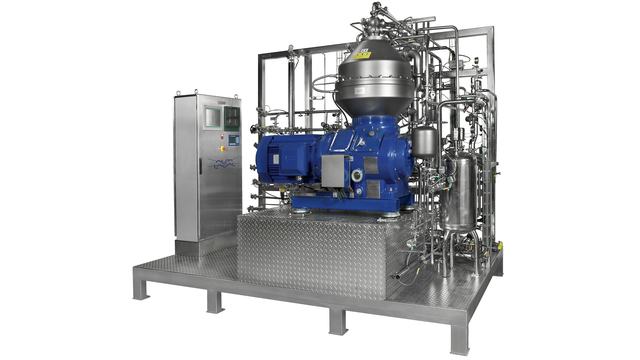

The Alfa Laval BTUX is a nozzle centrifuge designed for a wide range of biotech separation duties, particularly high-density fermentations that require continuous solids discharge.

Experience the benefits of BTUX, centrifugal separation for biotechnology

- Self-regulating vortex nozzles for optimal concentrate dryness and minimum clogging risk

- High efficiency – can be run close to clogging point

- Low energy is required to recover solids in closed system under pressure

- Hygienic design, with options for steam sterilization and contained operation

- Suitable for process lines equipped with automated CIP – available with automatic ejection of washed solids during cleaning cycle

The BTUX nozzle centrifuge is available in different sizes to cover a range of process requirements for microbials separation, such yeast and bacteria. The solids content in the feed typically ranges from 1–20% by volume but may vary depending on the specific application.

Learn more about BTUX nozzle centrifuges

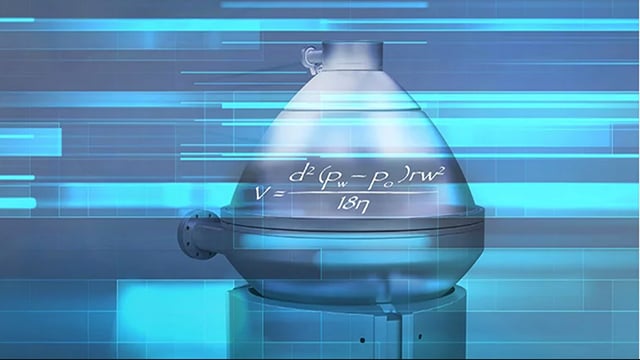

BTUX separators are designed to allow solids to flow easily in the bowl, even against centrifugal force. This means low energy consumption within a closed, pressurized, and hygienic system.

Inside the disc-type bowl, solids pass through concentrate tubes and vortex nozzles, and are discharged under pressure via a paring tube. The clarified liquid moves toward the center and is also discharged under pressure. Solids can be automatically ejected during cleaning cycles, making the system ideal for CIP lines.

Self-regulating vortex nozzles

Alfa Laval’s vortex nozzles automatically adjust to variations in feed flow and solids content, maintaining a consistent solids concentration. The inlet and outlet pressures are comparable to standard pressure drops and remain stable, regardless of concentrate viscosity.

Concentrate enters tangentially, spins in the nozzle chamber, and exits through a central outlet. This design allows operation close to the clogging point without increasing blockage risk.

Complete system

BTUX units come in various sizes and can include the separator, motor, solids cyclone, switchgear and starter, control panel, valve cluster, flow meter, sight glasses, flexible connections, and other auxiliary equipment.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.

Test, validate, and scale up your next separation solution

Whether upgrading your production line or running a proof of concept, Alfa Laval helps you choose the right separator solution with confidence. Simply get in touch to arrange a consultation and trial at one of our test centres, or to rent a unit for onsite testing.